+86-180 3665 1199

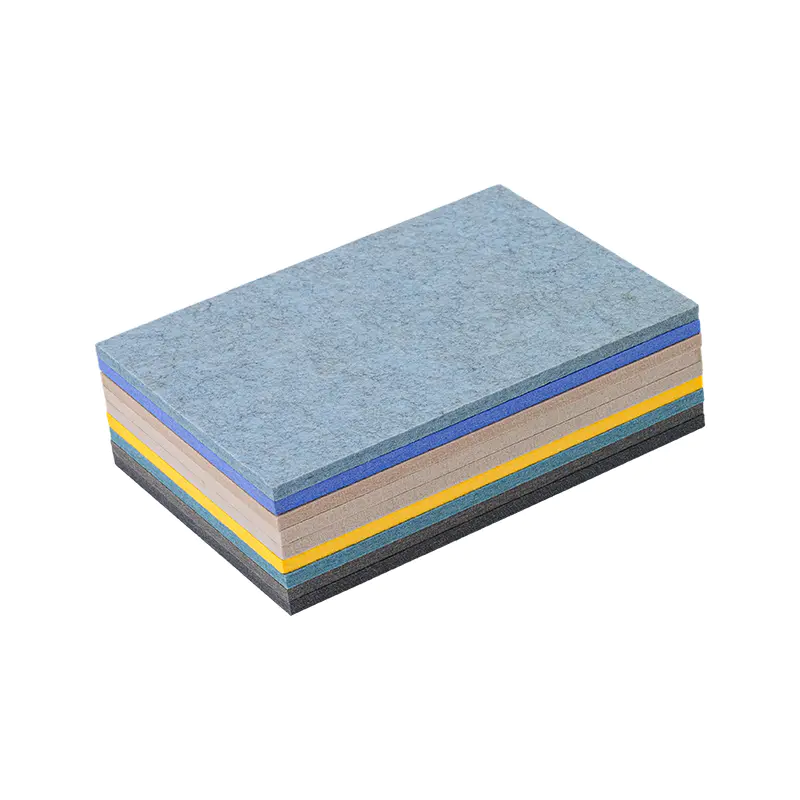

Acoustic design is a critical component of modern interior engineering, where the goal is to manage reverberation and improve speech intelligibility. Acoustic PET panels have become the industry standard for these applications due to their high performance and sustainability. Yayin New Materials Jiangsu Co., Ltd., headquartered in Lianyungang with over 30,000 square meters of production space, specializes in carbon-neutral polyester fiber antibacterial materials. Our acoustic PET panels utilize needle-punched non-woven technology to create environmentally friendly solutions that are flame-retardant (ASTM E84 A level), heat-insulating, and decorative. Understanding the specific installation nuances on various substrates is essential to achieving our tested Noise Reduction Coefficient (NRC) of 0.85.

1. Substrate Analysis: Preparing Surfaces for Acoustic PET Panels

Before beginning an installation, an engineer must evaluate the porous or non-porous nature of the wall. When considering how to hang acoustic PET panels, the surface texture dictates the adhesive chemistry required. For porous surfaces like drywall or timber, water-based construction adhesives or spray adhesives work effectively. However, non-porous surfaces like glass or polished concrete require specialized mechanical fasteners or high-bond double-sided tapes to ensure long-term stability without damaging the acoustic PET panels.

Compared to heavy mineral wool boards, the lightweight nature of acoustic PET panels allows for more versatile mounting options on delicate surfaces, though surface tension must always be neutralized by cleaning before application.

| Wall Surface Type | Recommended Attachment Method | Surface Preparation Required |

| Drywall / Plaster | Heavy-duty spray adhesive or Z-clips | Dust removal and priming |

| Concrete / Masonry | Construction adhesive or furring strips | Leveling and moisture checking |

| Glass / Metal | High-bond VHB tape or suction mounts | Alcohol degreasing |

2. Optimizing NRC: The Impact of Air Gaps and Spacing

The installation method directly influences the acoustic PET panels NRC rating. While flush-mounting panels to a wall is the most common aesthetic choice, engineers often specify an "air gap" installation to improve low-frequency absorption. By using furring strips to create a 20mm to 50mm space between the panel and the wall, the panel acts as a membrane absorber, effectively doubling the sound-dampening efficiency for bass frequencies. This is a vital consideration when determining what is the best thickness for acoustic PET panels; a thinner panel with an air gap can often outperform a thicker panel mounted flush.

While flush mounting is simpler and saves space, the air-gap method provides a significant boost in the absorption of mid-to-low range frequencies that typically bypass thin surface treatments.

| Installation Style | NRC Performance Impact | Best Use Case |

| Flush Mount | Standard (Optimized for high frequencies) | Offices, hallways, general speech |

| Offset (Air Gap) | Enhanced (Improved low-mid frequency) | Studios, home theaters, mechanical rooms |

| Suspended (Cloud) | Maximum (Absorption on both sides) | High-ceiling lobbies, open-plan cafes |

3. Mechanical vs. Adhesive Fastening for Long-Term Durability

The choice between mechanical and adhesive fastening often depends on whether the installation is permanent or modular. Yayin New Materials ensures our panels are E0 level for formaldehyde emission, making them safe for any indoor environment. For permanent installations, high-tack adhesives provide a seamless look. However, for those asking are acoustic PET panels easy to remove, mechanical systems like impaling clips or hook-and-loop (Velcro) systems are superior as they allow for panel rotation or relocation during office reconfigurations.

- Adhesives: Provide a clean, "edge-to-edge" finish but can damage the substrate upon removal.

- Z-Clips: Offer precise alignment and ease of removal for maintenance or cleaning.

- Impaling Clips: Fastest mechanical method, ideal for dense acoustic PET panels in high-traffic areas.

4. Fire Safety and Compliance in Installation

When installing acoustic PET panels in public buildings, compliance with international fire codes is mandatory. The material from Yayin New Materials Jiangsu Co., Ltd. reaches the A level of US standard ASTM E84 and B level of EU standard EN13501-1. During installation, it is critical not to use flammable adhesives that could compromise the fire rated acoustic PET panels' performance. Engineers must ensure that all gaps are properly sealed if the panels are used as part of a fire-rated partition wall.

Unlike many organic foam alternatives that release toxic smoke, our recyclable polyester materials are engineered for low smoke development (UL723-2018 A level) and high thermal resistance.

Frequently Asked Questions (FAQ)

1. Can I cut acoustic PET panels to fit around outlets?

Yes. Acoustic PET panels can be easily cut using a sharp heavy-duty utility knife and a straight edge. Their non-fraying, needle-punched structure allows for precision cutouts without losing structural integrity.

2. How do I clean the panels after installation?

For regular maintenance, vacuuming the surface is sufficient. For stains, a mild detergent and warm water can be used. Because Yayin panels are antibacterial and water-resistant, they do not harbor mold or odors.

3. Are these panels suitable for humid environments like gyms?

Absolutely. Acoustic PET panels are resistant to moisture and do not rot. They provide excellent sound absorption in high-reverberation spaces like gymnasiums and indoor pools.

4. Do acoustic PET panels block noise from neighbors?

It is important to distinguish between "sound absorption" (reducing echo inside a room) and "soundproofing" (blocking sound between rooms). While our panels significantly improve the internal environment, they should be paired with mass-loaded vinyl if the primary goal is sound isolation.

5. What makes Yayin panels "carbon-neutral"?

Our panels are made from recycled PET plastic bottles. By diverting waste from landfills and using energy-efficient manufacturing processes in our 30,000 m2 facilities, we minimize the carbon footprint of our acoustic PET panels.

Industry References

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.

- EN 13501-1: Fire classification of construction products and building elements.

- ISO 9001:2015 & ISO 14001:2015: Quality and Environmental Management Systems.

- UL 723-2018: Standard for Test for Surface Burning Characteristics of Building Materials.