+86-180 3665 1199

In modern commercial and public architecture, the integration of **Acoustic Sound Proof Panels** must be architecturally harmonious. B2B buyers—including designers and project managers—require solutions where **Acoustic panel customization** requirements can be met without degrading certified sound absorption performance (e.g., NRC} 0.85) or compromising critical safety standards. Yayin New Materials specializes in carbon-neutral polyester fiber materials, which inherently offer superior decorative flexibility alongside fire safety (ASTM E} 84 Class A), allowing for truly **Aesthetic acoustic panel** design.

Customization and Design Flexibility

The flexibility of the polyester fiber core allows for unprecedented customization in form and graphics.

Mastering Acoustic panel customization requirements

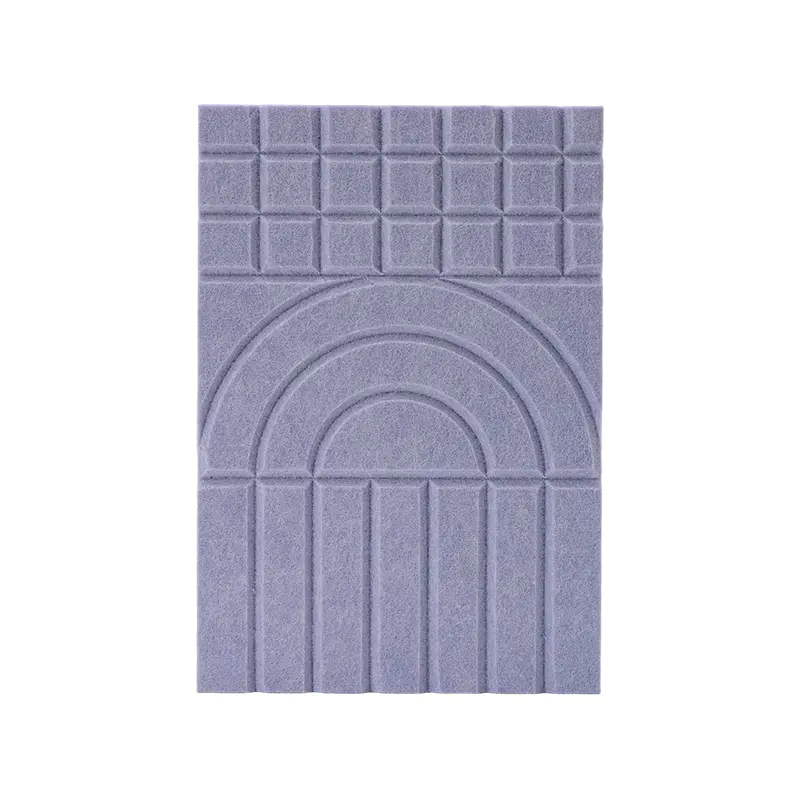

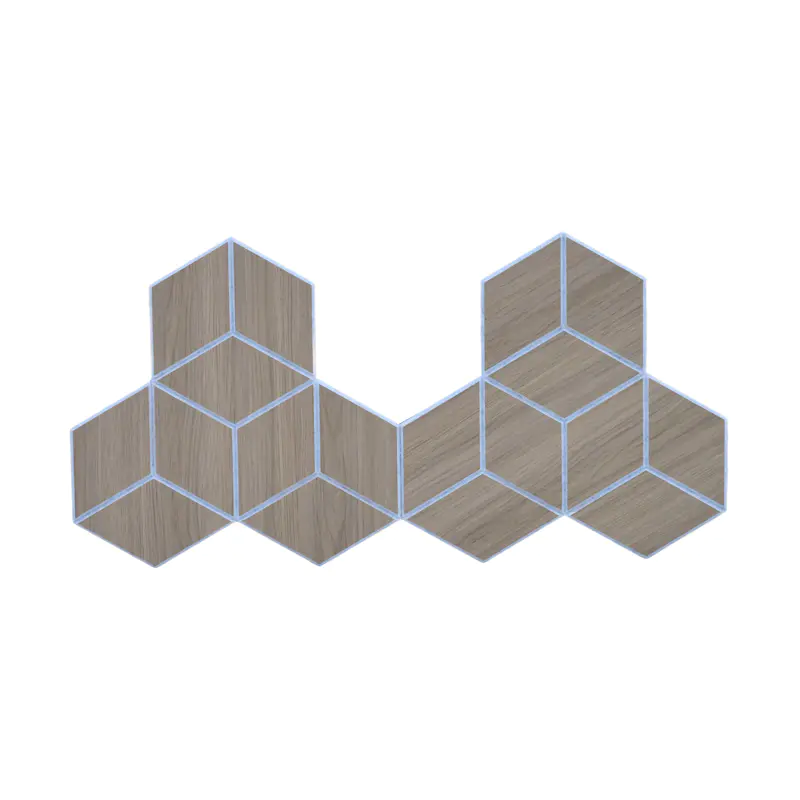

**Acoustic panel customization** requirements extend beyond color to shape and installation. Designers frequently specify complex geometries, such as hexagonal, curved, or precisely cut dimensional patterns, which polyester fiber materials can easily accommodate due to their uniform density and ease of machining. Precise edge detailing (square, bevel, or rounded) is vital for achieving a professional, finished look upon installation.

The technical process of Custom printed acoustic panels

The creation of **Custom printed acoustic panels** relies on UV- or dye-sublimation printing applied directly to the porous polyester surface. The key technical challenge is ensuring the ink layer is thin and non-occlusive, preventing it from blocking the thousands of micro-cavities responsible for sound absorption. Successful printing must maintain the fabric's acoustic transparency, ensuring the NRC value remains consistent with the unprinted material.

Finish Selection and Performance

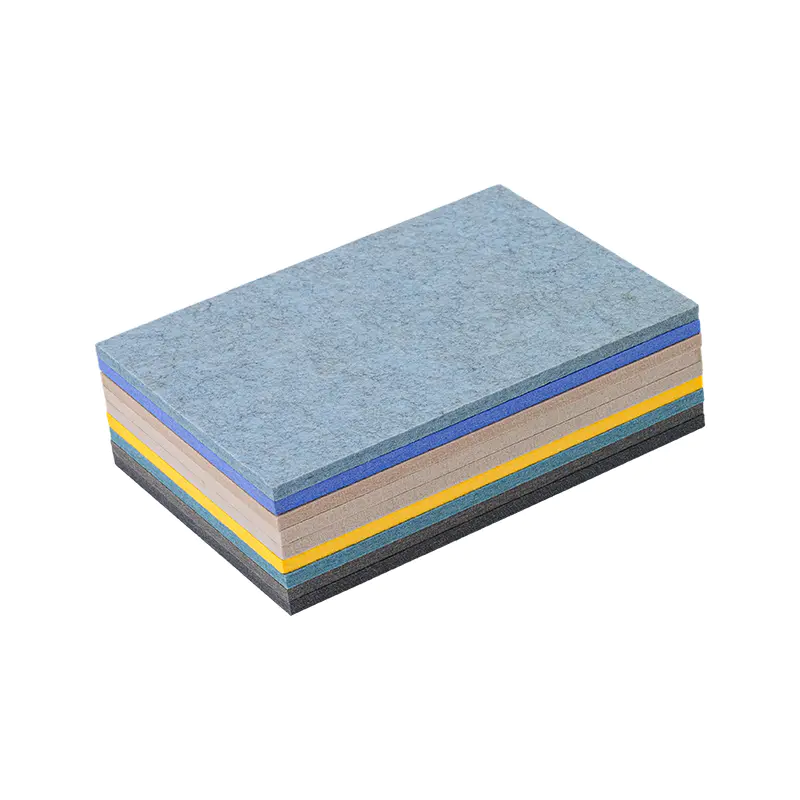

The choice of finish is a trade-off between aesthetic goals, durability, and acoustic transparency.

Impact of Acoustic panel fabric finish options on NRC

The **Acoustic panel fabric finish** options are the most visible component. While covering the porous acoustic core protects it, the fabric must be acoustically transparent to allow sound waves to penetrate. Open-weave textiles (like standard polyester or fiberglass cloth) allow sound through with minimal reflection, preserving the high NRC of the core. Conversely, thick vinyl or non-porous coatings will reflect high-frequency sound, subtly but measurably reducing the overall NRC rating.

Comparison: Finish Type vs. NRC Impact vs. Durability:

| Finish Type | Primary NRC Impact | Durability/Maintenance |

|---|---|---|

| Open-Weave Fabric | Minimal reduction (Excellent transparency) | Good (Best for controlled environments) |

| Perforated Metal/Wood | Controlled reduction (Acoustically engineered) | Excellent (Best for high-traffic or impact areas) |

Designing the Aesthetic acoustic panel for purpose

Designing the **Aesthetic acoustic panel** involves selecting the appropriate finish based on the application's demands. For high-traffic areas, a perforated metal or rigid wood finish may be necessary for durability, even if it slightly lowers the mid-to-high frequency NRC. For conference rooms, a soft **Acoustic panel fabric finish** provides maximum sound absorption and a warmer aesthetic. The core goal is achieving the required NRC with the least intrusive and most appealing decorative solution.

Safety and Compliance Integration

Aesthetics are only viable when coupled with verified fire and environmental safety.

Non-negotiable: Fire rated acoustic panels for interiors

For any commercial project, specifying **Fire rated acoustic panels** for interiors is a non-negotiable requirement for compliance and life safety. Our polyester fiber panels achieve Class A ratings under the ASTM E} 84 standard, meaning both the sound-absorbing core and the decorative finish have extremely low flame spread and smoke development indices. Procurement must demand proof that all aspects, including glues and finishes used for **Custom printed acoustic panels**, meet these standards.

Certifying the final product

Yayin New Materials maintains rigorous control over the entire supply chain to ensure quality and compliance. We hold ISO} 9001 and ISO} 14001 certifications, guaranteeing that all **Acoustic Sound Proof Panels**—whether standard or highly customized—adhere to global benchmarks. Our commitment extends to environmental safety, verified by an E} 0 formaldehyde emission test, ensuring the **Aesthetic acoustic panel** is safe for all interior environments.

Conclusion

B2B procurement of **Acoustic Sound Proof Panels** must ensure that **Acoustic panel customization** requirements enhance, not degrade, the certified acoustic performance. Verifying the acoustic permeability of **Acoustic panel fabric finish** options and the Class A certification of **Fire rated acoustic panels** for interiors are essential steps for any project manager. Yayin New Materials offers the technical expertise and high-performance, carbon-neutral polyester materials to deliver highly effective **Custom printed acoustic panels** and other decorative solutions that meet both aesthetic and engineering standards.

Frequently Asked Questions (FAQ)

- Can I use any standard upholstery fabric as an **Acoustic panel fabric finish**? No. Standard upholstery fabrics are often too dense, which reflects high-frequency sound waves, reducing the panel's effectiveness. You must use acoustically transparent fabrics, which allow sound to pass through to the core.

- How does the NRC of a **Custom printed acoustic panels** compare to the plain panel? A high-quality UV or dye-sublimation printed panel should maintain the same NRC as the plain panel, provided the ink does not form a continuous, non-porous film over the surface. Always request verified NRC data for the final printed product.

- What is the typical fire rating required for **Fire rated acoustic panels** for interiors in commercial spaces? The minimum requirement for wall and ceiling finishes in most commercial buildings is Class A (ASTM E} 84) or B (EN} 13501-1), which our materials are certified to meet.

- How do **Acoustic panel customization** requirements affect lead time? While standard shapes are fast, complex customization (e.g., non-standard shapes, multi-color **Custom printed acoustic panels**) requires additional programming and testing, typically adding 1 to } 3 weeks to the standard lead time.

- Do recessed mounting systems affect the NRC of **Acoustic Sound Proof Panels**? Mounting methods can affect NRC. A Z-Clip or rigid mounting system leaves an air gap behind the panel, which can slightly increase low-frequency absorption compared to direct contact (glued) installation.