+86-180 3665 1199

- 1 Evaluating Installation Methods for Acoustic Panels

- 2 Achieving Stability and Aesthetic Integration

- 3 Maintenance and Longevity: Designing for Access

- 4 Yayin New Materials: Defining Performance and Sustainability

- 5 Frequently Asked Questions (FAQ)

- 5.1 1. What are the key benefits of using Removable mounting systems for acoustic wall panels?

- 5.2 2. How do Hidden fastener methods for decorative sound absorbing panels ensure stability without compromising aesthetics?

- 5.3 3. When is Suspended acoustic panel installation vs direct-fix the better choice?

- 5.4 4. What design strategy ensures Simplified maintenance of sound absorbing wall panels?

- 5.5 5. What is the main factor in achieving robust Acoustic panel mounting security and ease of access?

The functionality of Decorative Sound Absorbing Panels extends far beyond their measured Noise Reduction Coefficient. For commercial and architectural projects, the mounting system is a critical engineering component, directly impacting installation efficiency, long-term stability, and the ease of routine maintenance. The ideal system must balance robust Acoustic panel mounting security and ease of access, ensuring the panel remains securely fixed while allowing simple, non-destructive removal for cleaning or accessing underlying utilities.

Carved Art Adhesive Acoustic Panels 3d Panel Acoustic Panel Polyester Fiber

Evaluating Installation Methods for Acoustic Panels

Engineers must weigh the benefits of permanent versus demountable mounting methods based on the project's long-term access requirements.

Direct-Fix Adhesion vs. Mechanical Attachment

- Direct-Fix (Adhesion): This uses structural adhesive to permanently bond the Decorative Sound Absorbing Panels to the substrate. It offers high initial stability and minimal profile but severely restricts future maintenance access and causes wall damage upon removal.

- Mechanical Attachment: Utilizing clips, Z-bars, or impaling fasteners provides a secure connection that, when designed correctly, can facilitate easy removal and re-installation, supporting the need for Removable mounting systems for acoustic wall panels.

Comparing Suspended acoustic panel installation vs direct-fix in Commercial Spaces

When comparing Suspended acoustic panel installation vs direct-fix, suspension systems (clouds or baffles) often offer better access to utilities and superior low-frequency absorption due to the air gap created. Direct-fix methods are preferred when a seamless, integrated wall appearance is the primary design goal, but they compromise access.

Installation Method Comparison Table

| Mounting System Type | Ease of Removal/Maintenance Access | Wall/Ceiling Substrate Damage |

|---|---|---|

| Direct-Fix (Adhesive) | Difficult/Low | High (Destructive removal) |

| Mechanical Z-Clip/Hidden Fastener | Easy/High | Minimal (Reusable attachment points) |

Achieving Stability and Aesthetic Integration

A successful installation combines maximum holding strength with minimal visual intrusion.

Technical Specifications of Hidden fastener methods for decorative sound absorbing panels

- Z-Clips & Rotational Fasteners: These offer a solution for Hidden fastener methods for decorative sound absorbing panels. Z-clips rely on an interlocking, gravity-based system for vertical support and can be easily lifted for removal. Rotational fasteners or specialised anchors ensure secure mechanical coupling while keeping the fixing mechanism completely invisible, preserving the aesthetic integrity of the panel's surface.

- Load Bearing: The chosen fastener system must be rated to support the full dead load of the panel with a minimum safety factor (typically ge 4:1) under all environmental conditions.

Enhancing Acoustic panel mounting security and ease of access

The trade-off between security and access is managed through design. Systems engineered for high seismic zones may require additional locking mechanisms to guarantee Acoustic panel mounting security and ease of access only when specific tools or knowledge are applied, ensuring compliance with local building codes while maintaining accessibility for authorized personnel only.

Maintenance and Longevity: Designing for Access

Long-term maintenance costs are reduced significantly by specifying demountable panels.

Strategies for Simplified maintenance of sound absorbing wall panels

- Demountable Systems: Specifying Removable mounting systems for acoustic wall panels is the primary strategy for Simplified maintenance of sound absorbing wall panels. Panels secured via Z-clips or mechanical fasteners can be quickly lifted and removed for deep cleaning, repair, or to facilitate access to wiring, or plumbing located behind the wall surface.

- Material Focus: The surface material itself should be inherently durable, resistant to fungal growth, and cleanable with approved non-abrasive methods to reduce the need for panel removal.

Minimizing Substrate Damage during Panel Removal

Systems relying on minimal, reusable attachment points (like screws into anchors) cause less damage to the substrate than large adhesive patches. This modular approach is essential in leased commercial spaces where the substrate must be returned to its original condition.

Yayin New Materials: Defining Performance and Sustainability

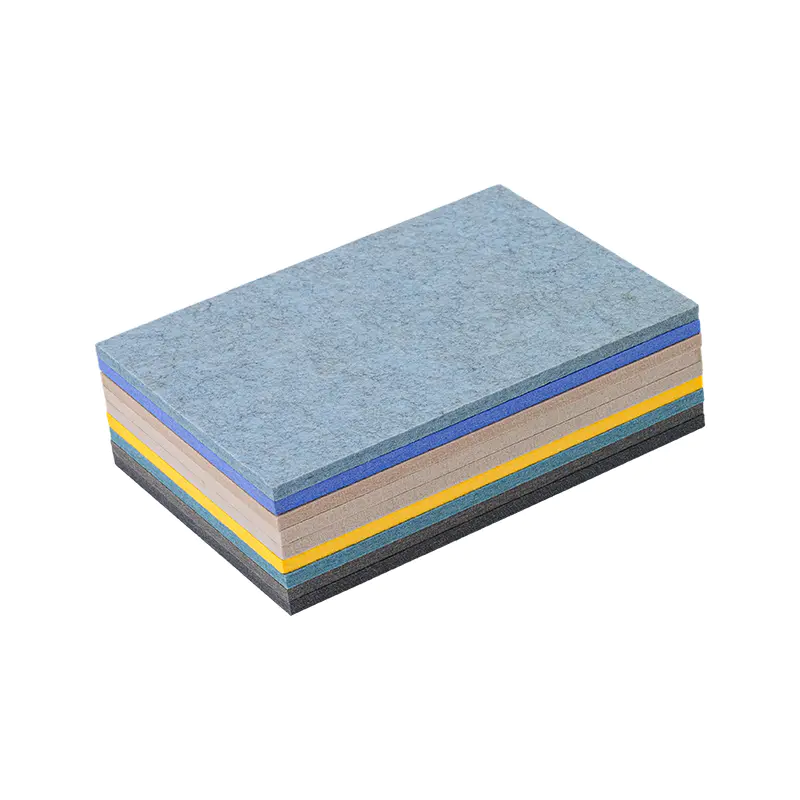

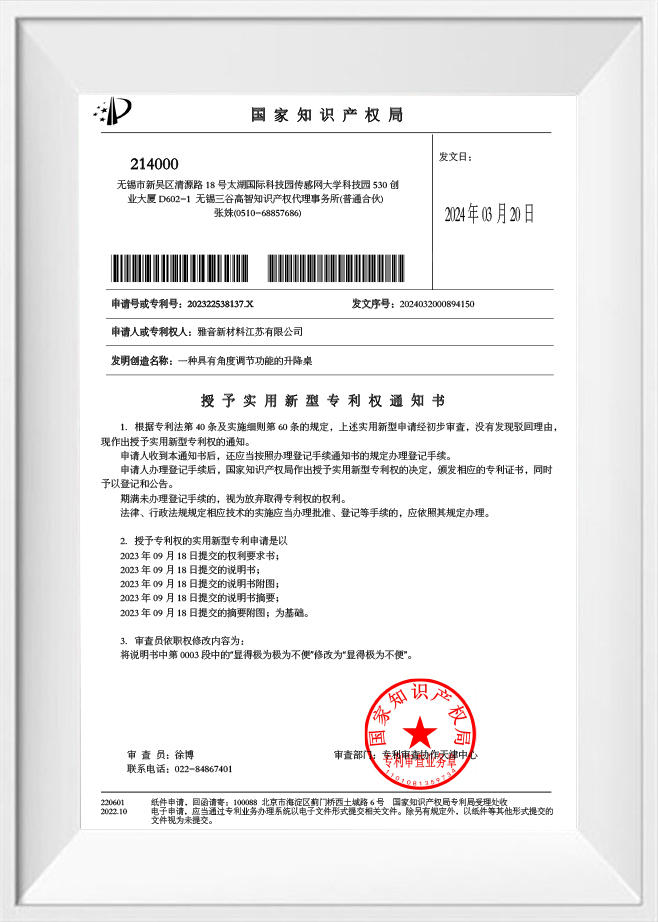

Yayin New Materials Jiangsu Co., Ltd. specializes in the R&D, production, and sales of carbon-neutral polyester fiber antibacterial sound-absorbing materials. Operating across three modern facilities with over 30,000 square meters of production space, we leverage needle-punched non-woven technology to create environmentally friendly panels that are sound-absorbing, flame-retardant and highly decorative. Our panels achieve a tested, ensuring superior acoustic performance. We design our Decorative Sound Absorbing Panels with compatible mounting hardware, promoting Acoustic panel mounting security and ease of access for installers. Our focus on quality is verified by ISO9001 and ISO14001 certifications, ensuring that our products—from material composition to installation compatibility—meet the highest standards for performance, safety (E0 formaldehyde emission), and sustainable building design.

Frequently Asked Questions (FAQ)

1. What are the key benefits of using Removable mounting systems for acoustic wall panels?

The key benefits are improved access for maintenance (cleaning or utility repair), reduced damage to the substrate upon removal, and the ability to easily relocate or reconfigure the panels.

2. How do Hidden fastener methods for decorative sound absorbing panels ensure stability without compromising aesthetics?

Hidden fasteners like Z-clips or specialised anchors mechanically secure the panel to the wall or ceiling structure, providing a robust hold while being completely concealed behind the panel edges, thus maintaining a clean, uninterrupted decorative surface.

3. When is Suspended acoustic panel installation vs direct-fix the better choice?

Suspended installation (baffles or clouds) is typically better when seeking maximum acoustic performance, as the air gap created behind the panel enhances low-frequency absorption. It is also preferred when ceiling access is required.

4. What design strategy ensures Simplified maintenance of sound absorbing wall panels?

The primary strategy is specifying materials that are inherently cleanable (e.g., high-density PET fiber) and utilizing mechanical mounting systems that allow quick and easy, non-destructive removal of the panel for thorough cleaning or repair.

5. What is the main factor in achieving robust Acoustic panel mounting security and ease of access?

The main factor is the fastener design. Systems should use high-quality, load-rated mechanical clips that prevent accidental dislodgement while requiring only a simple lifting or rotating action for intentional removal by technicians.