+86-180 3665 1199

- 1 1. Fire Safety Compliance: Navigating Global Flame Retardant Standards

- 2 2. VOC Emissions and Indoor Air Quality (IAQ) in Libraries

- 3 3. Acoustic Performance: NRC and High-Density Engineering

- 4 4. Sustainable Manufacturing and Carbon Neutrality

- 5 5. Conclusion: A Holistic Approach to Library Safety

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. What is the difference between fire resistant vs fire retardant acoustic panels?

- 6.2 2. Does a higher density Acoustic Desk Screens mean better soundproofing?

- 6.3 3. What are the benefits of E0 grade acoustic desk screens for students?

- 6.4 4. How to clean polyester acoustic desk screens without damaging the fire rating?

- 6.5 5. Can recycled polyester fiber acoustic screens be used in moisture-prone areas?

- 7 Related Industry References

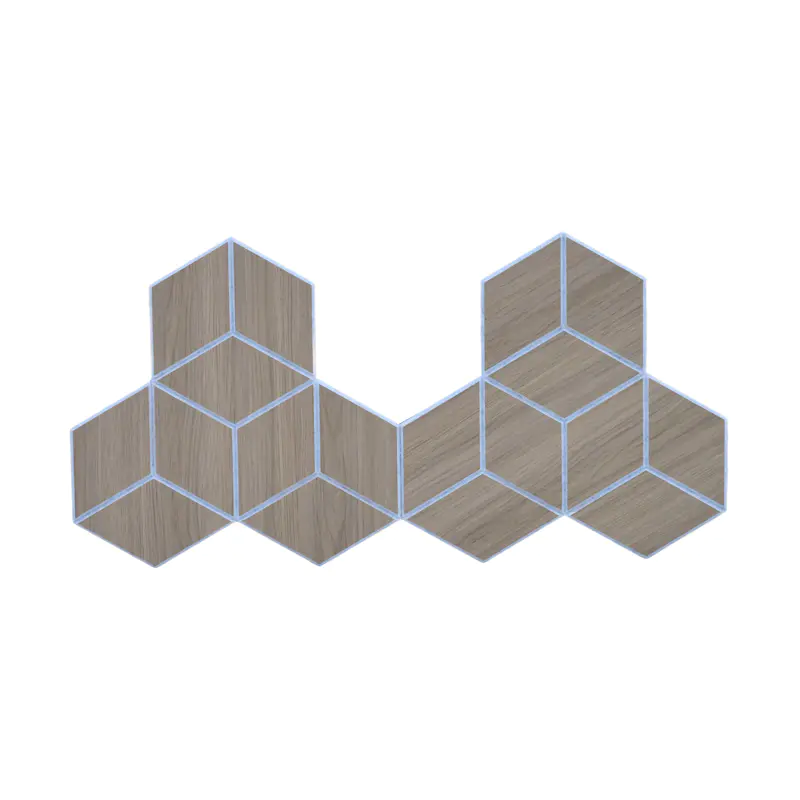

In the architectural design of modern educational environments, the integration of Acoustic Desk Screens has become essential for managing ambient noise and fostering deep focus. However, when these panels are installed in high-occupancy areas like school libraries, their aesthetic and acoustic properties must be secondary to stringent safety protocols. Yayin New Materials Jiangsu Co., Ltd., headquartered in Lianyungang with over 30,000 square meters of production capacity, specializes in carbon-neutral polyester fiber solutions. Our engineered panels utilize needle-punched non-woven technology to achieve a high Noise Reduction Coefficient (NRC) of 0.85 while adhering to global fire and emission standards. Understanding the specific acoustic panel fire rating ASTM E84 and the implications of VOC off-gassing is vital for ensuring a safe learning atmosphere.

In school libraries, fire propagation is a critical concern due to the high density of flammable paper materials. Acoustic Desk Screens must serve as a barrier rather than a fuel source. High-density polyester panels are engineered to be self-extinguishing and low-smoke producing. While standard materials may melt or contribute to flashover, Yayin's panels achieve the A level of the US standard ASTM E84 and the B level of the EU standard EN13501-1. When comparing fire resistant vs fire retardant acoustic panels, it is important to note that fire-retardant materials are chemically or structurally treated to slow the spread of fire, whereas "fire-resistant" implies a material that maintains its structural integrity under heat. For school environments, a high flame-spread index rating is the mandatory engineer-level requirement.

| Standard ID | Rating/Classification | Safety Implication |

| ASTM E84 (USA) | Class A / Level A | Flame Spread Index 0-25; Smoke Developed 0-450 |

| EN13501-1 (EU) | Class B, s1, d0 | Very limited contribution to fire; little to no smoke/droplets |

| UL723-2018 (EU) | Level A | Verified surface burning characteristics for architectural use |

2. VOC Emissions and Indoor Air Quality (IAQ) in Libraries

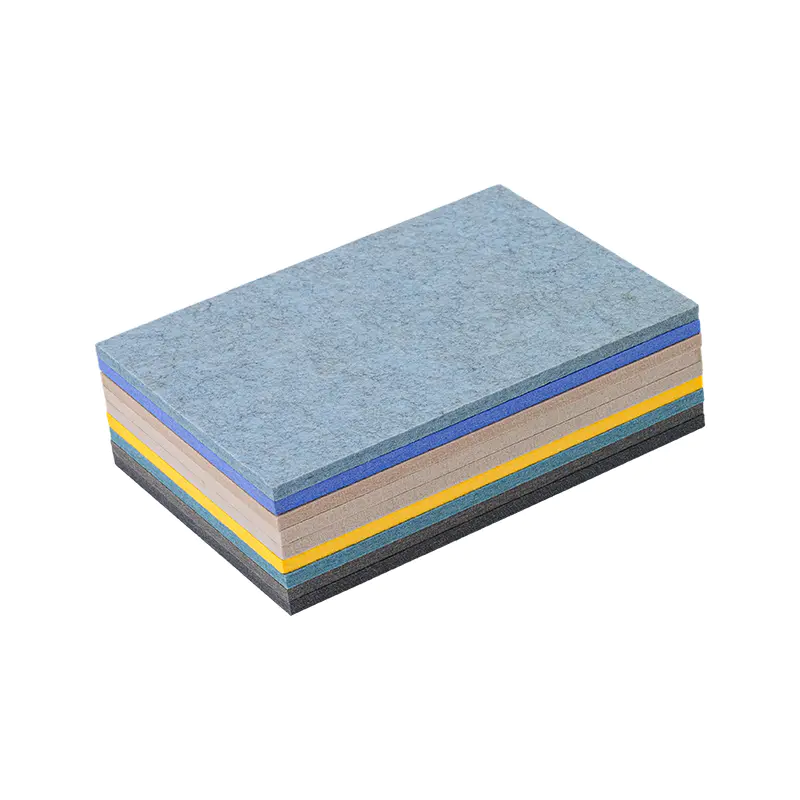

Volatile Organic Compounds (VOCs) and formaldehyde are primary contributors to "Sick Building Syndrome," which can impair student cognitive function. Low VOC office dividers and desk screens are manufactured without the use of toxic binders or formaldehyde-based resins. The benefits of E0 grade acoustic desk screens are measurable; they ensure that formaldehyde emission levels are below 0.5 mg/L, meeting the strictest international health standards. At Yayin New Materials, our needle-punching process uses mechanical interlocking of fibers rather than chemical glues, ensuring our products are not only recyclable but also safe for prolonged proximity to students in confined library carrels.

| Standard Grade | Formaldehyde Emission Limit | Safety Verdict for Schools |

| E2 Grade | ≤ 5.0 mg/L | Unsuitable for indoor educational use |

| E1 Grade | ≤ 1.5 mg/L | Acceptable for general construction |

| E0 Grade (Yayin) | ≤ 0.5 mg/L | Recommended for libraries and medical environments |

3. Acoustic Performance: NRC and High-Density Engineering

The core function of Acoustic Desk Screens is the absorption of high and mid-frequency sound waves. A Noise Reduction Coefficient (NRC) of 0.85 means that the panel absorbs 85% of the sound energy hitting it. For school libraries, how to clean polyester acoustic desk screens is a common operational question, as dust accumulation can theoretically impact the porosity—and thus the NRC—over time. High-density polyester fiber is inherently resistant to moisture and bacteria, allowing for dry-vacuuming or steam cleaning without degrading the acoustic matrix. This durability ensures that the screens provide long-term heat-insulating and decorative value without losing their sound-dampening capabilities.

4. Sustainable Manufacturing and Carbon Neutrality

Modern procurement for schools emphasizes the use of recycled polyester fiber acoustic screens. Yayin's focus on carbon-neutral polyester fiber antibacterial sound-absorbing materials aligns with global sustainability goals. By utilizing needle-punched non-woven technology, we transform post-consumer PET into high-performance panels. This process is significantly more energy-efficient than traditional glass-wool production. When evaluating acoustic desk screens for open plan offices and libraries, engineers prioritize materials that are 100% recyclable, ensuring that the product's end-of-life cycle does not contribute to landfill waste.

| Attribute | Traditional Fiberglass Panels | Yayin Carbon-Neutral Polyester |

| Recyclability | Difficult / Low | 100% Recyclable |

| Installation Safety | Requires PPE (Fiber irritation) | Non-toxic / No PPE required |

| Moisture Resistance | High (But can harbor mold) | Naturally Hydrophobic / Antibacterial |

5. Conclusion: A Holistic Approach to Library Safety

The installation of Acoustic Desk Screens in school libraries requires a holistic approach that balances acoustic absorption with life-safety compliance. By adhering to the acoustic panel fire rating ASTM E84 and maintaining E0-level formaldehyde emissions, Yayin New Materials Jiangsu Co., Ltd. provides a technical solution that protects both the ears and the lungs of the next generation. Our ISO9001 and ISO14001 certified processes guarantee that high-density polyester fiber panels are the professional choice for any high-standard educational project.

Frequently Asked Questions (FAQ)

1. What is the difference between fire resistant vs fire retardant acoustic panels?

Fire-retardant panels, like Yayin's polyester fiber, are treated or manufactured to slow down the combustion process and reduce smoke. Fire-resistant panels are generally made of non-combustible materials like mineral wool that can withstand direct fire for specified time ratings.

2. Does a higher density Acoustic Desk Screens mean better soundproofing?

Not necessarily soundproofing (blocking sound), but higher density usually improves sound "absorption" (reducing echo). High-density panels provide better structural rigidity and more fiber surface area to dissipate sound energy as heat.

3. What are the benefits of E0 grade acoustic desk screens for students?

E0 grade ensures that the air quality in the library remains pristine. It prevents the inhalation of formaldehyde, which can cause headaches, dizziness, and long-term respiratory issues in children and young adults.

4. How to clean polyester acoustic desk screens without damaging the fire rating?

Since the flame-retardant properties are inherent to the polyester fiber structure or integrated during the needle-punching process, you can clean them with a vacuum or mild detergent without "washing away" the fire protection.

5. Can recycled polyester fiber acoustic screens be used in moisture-prone areas?

Yes. Polyester is naturally hydrophobic and does not support the growth of mold or mildew, making it a superior choice compared to traditional fabric-wrapped wood or glass fiber boards in humid library basements.

Related Industry References

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.

- EN 13501-1: Fire classification of construction products and building elements.

- ISO 9001 & 14001: Quality and Environmental Management Systems Standards.

- UL 723-2018: Standard for Test for Surface Burning Characteristics of Building Materials.