+86-180 3665 1199

- 1 1. The Lifecycle Sustainability of Polyester Fiber Panels

- 2 2. Contributing to LEED Certification Categories

- 3 3. Technical Performance: Fire Safety and NRC Metrics

- 4 4. Environmental Management and Quality Assurance

- 5 Conclusion: A Greener Path to Acoustic Excellence

- 6 Frequently Asked Questions (FAQ)

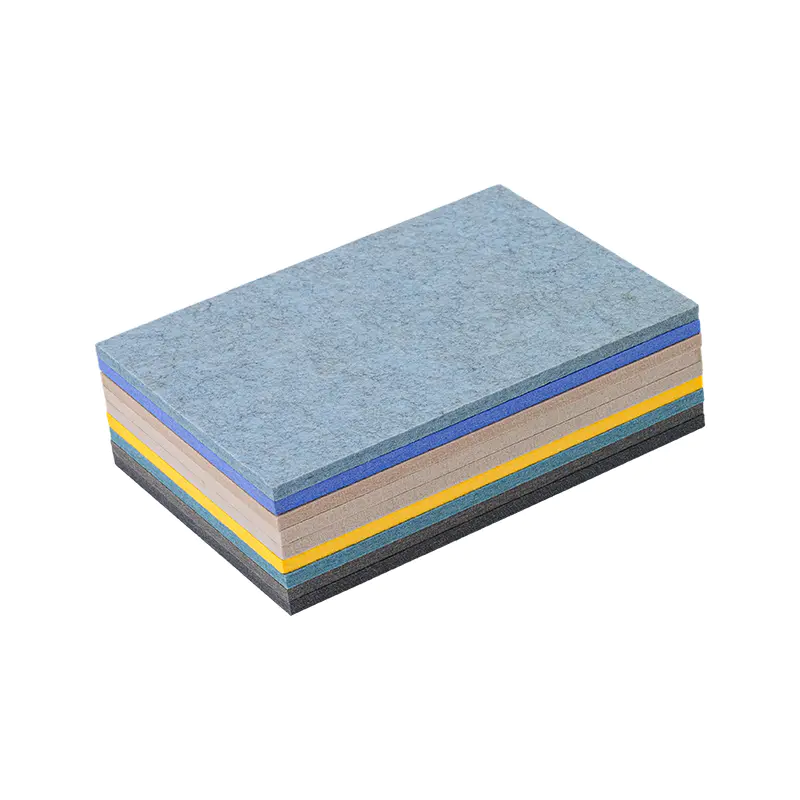

In the contemporary architectural landscape, the intersection of acoustic comfort and environmental stewardship has become a primary focus for engineers and interior designers. Acoustic PET Panels, manufactured from polyethylene terephthalate, have redefined the expectations for interior finish materials. Yayin New Materials Jiangsu Co., Ltd., headquartered in Lianyungang with over 30,000 square meters of production space across three provinces, leads this sector by specializing in carbon neutral acoustic wall panels. Our commitment to needle-punched non-woven technology transforms recyclable polyester into high-performance, carbon-neutral solutions that address noise, fire safety, and thermal insulation simultaneously.

1. The Lifecycle Sustainability of Polyester Fiber Panels

True sustainability is measured through a Circular Economy lens, evaluating the origin, use-phase, and end-of-life of a material. Acoustic PET Panels are inherently sustainable because they are primarily composed of post-consumer recycled plastic bottles. Unlike traditional fiberglass or mineral wool, which can be energy-intensive to produce and difficult to recycle, recyclable polyester sound absorbing panels can be reprocessed back into the manufacturing stream. Yayin's production process adheres to ISO14001 standards, ensuring that formaldehyde emissions reach the E0 level, which is essential for maintaining indoor air quality.

When comparing PET to traditional acoustic materials, the carbon footprint of polyester is significantly lower due to the reduced energy required for fiber extrusion versus the melting of minerals or glass.

| Feature | Acoustic PET Panels | Fiberglass/Mineral Wool |

| Material Origin | Recycled Post-Consumer PET | Virgin Minerals/Glass |

| End-of-Life | 100% Recyclable | Landfill (Non-recyclable) |

| Safety/Handling | Non-toxic, Non-irritant | Requires PPE (Skin/Lung irritant) |

Source: ISO 14021:2024 Environmental labels and declarations — Self-declared environmental claims

2. Contributing to LEED Certification Categories

For B2B procurement and commercial projects, Acoustic PET Panels serve as a versatile tool for accumulating LEED (Leadership in Energy and Environmental Design) points. Specifically, they contribute to the "Materials and Resources" (MR) and "Indoor Environmental Quality" (EQ) categories. Using ASTM E84 Class A acoustic PET ensures that the project meets strict life safety codes while also satisfying acoustic performance requirements. With a Noise Reduction Coefficient (NRC) reaching 0.85, these panels directly improve the "Acoustic Performance" credit by reducing reverberation times in open-plan offices and educational spaces.

In terms of certification impact, the ability of PET panels to act as both a decorative finish and an acoustic absorber reduces the total quantity of materials required on-site, thereby lowering the overall project embodied carbon.

| LEED Category | Contribution of PET Panels | Metric/Standard |

| Materials & Resources | Recycled Content & Circularity | Post-consumer recycled % |

| Indoor EQ | Low VOC / Formaldehyde Free | E0 Level Compliance |

| Acoustic Performance | High absorption (NRC 0.85) | ASTM C423 / ISO 354 |

Source: U.S. Green Building Council - LEED v4.1 Technical Guidelines 2024

3. Technical Performance: Fire Safety and NRC Metrics

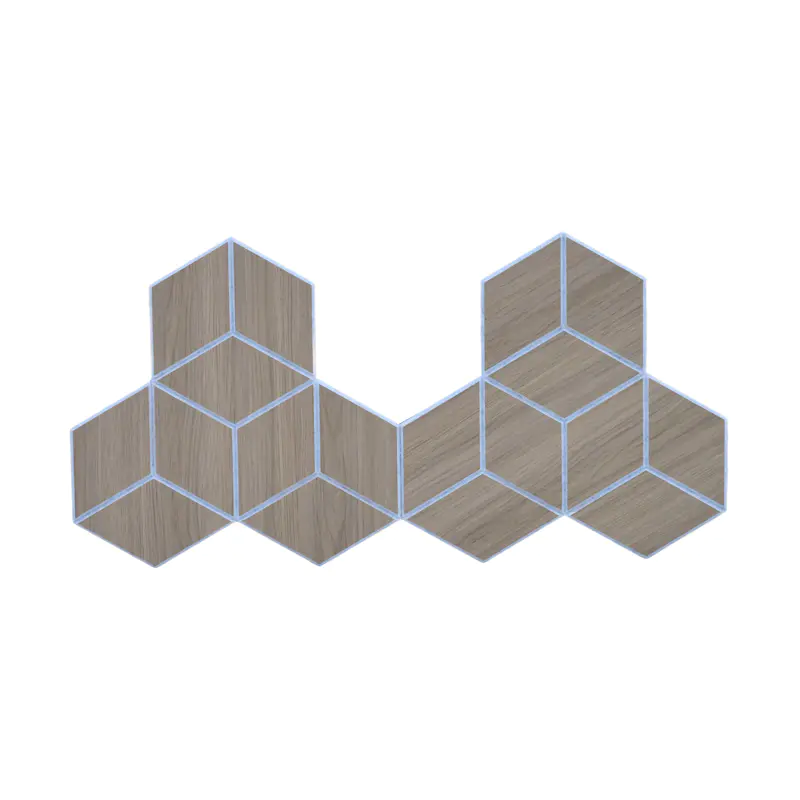

Engineering-grade Acoustic PET Panels must balance sustainability with high-order safety specifications. Yayin panels achieve the B level of the EU standard EN13501-1 and the A level of the US standard ASTM E84, alongside UL723-2018 certification. This ensures that flame retardant PET acoustic tiles can be safely integrated into public assembly areas. Furthermore, the NRC 0.85 polyester acoustic boards provide a porous structure that effectively dissipates sound energy, which is a significant breakthrough in needle-punched non-woven technology compared to older, less dense felt products.

Industry data from 2024 highlights that the acoustic market is shifting toward "Carbon-Neutral" verified materials, as global standards for net-zero construction become more stringent.

Source: ASTM E84-24 Standard Test Method for Surface Burning Characteristics of Building Materials

4. Environmental Management and Quality Assurance

To ensure consistent performance for B2B wholesalers, the manufacturing process must be tightly controlled. Yayin New Materials operates under ISO9001 and ISO14001 certifications, ensuring that every batch of Acoustic PET Panels maintains the same high standards of density and color consistency. By utilizing sustainable acoustic solutions for office design, developers are not only meeting current legislative requirements but are also future-proofing their assets against upcoming 2025-2026 environmental mandates.

Conclusion: A Greener Path to Acoustic Excellence

The transition to Acoustic PET Panels represents a technical evolution in building science. By choosing NRC 0.85 polyester acoustic boards that are both fire-rated and carbon-neutral, modern design can achieve acoustic perfection without environmental compromise. Yayin New Materials Jiangsu Co., Ltd. remains dedicated to advancing this technology, providing carbon neutral acoustic wall panels that empower architects to create spaces that are as silent as they are sustainable.

Frequently Asked Questions (FAQ)

- Can PET panels be recycled again after use?

Yes, our recyclable polyester sound absorbing panels are fully thermoplastic and can be ground down and re-processed into new polyester fibers at the end of their service life. - How do PET panels achieve a Class A fire rating?

Through precise chemical engineering of the fiber and the use of ASTM E84 Class A acoustic PET additives during the needle-punching process, ensuring the material does not support combustion. - Are these panels safe for schools and hospitals?

Absolutely. With E0 formaldehyde emission levels and antibacterial properties, they are ideal for high-hygiene sustainable acoustic solutions for office design and healthcare environments. - Does the NRC 0.85 rating require a specific thickness?

Typically, an NRC of 0.85 is achieved with 12mm or 24mm high-density panels, sometimes utilized with an air gap to maximize low-frequency absorption. - How many LEED points can I earn using Yayin panels?

While points depend on the total project scope, our panels contribute to multiple credits under the MR and EQ categories, helping significantly toward Gold or Platinum certification.