+86-180 3665 1199

- 1 I. The Importance of Installation in Acoustic Performance

- 2 II. Installation Protocol: Balancing Speed and Adhesion

- 3 III. Common Fixation Techniques and Hardware Selection

- 4 IV. Solutions for High-Efficiency Projects

- 5 V. Compliance and Material Assurance

- 6 VI. Simplicity Meets Specification

- 7 VII. Frequently Asked Questions (FAQs)

- 7.1 Q1: Which installation method provides the best sound absorption for Acoustic Wall Panels?

- 7.2 Q2: What is the main benefit of the removable acoustic wall panels mounting system for commercial clients?

- 7.3 Q3: When securing acoustic wall panels to drywall using adhesives, what is the best practice?

- 7.4 Q4: Are quick-install polyester acoustic panels for offices compliant with fire safety standards?

- 7.5 Q5: Why is acoustic panels mounting hardware selection important for precision?

I. The Importance of Installation in Acoustic Performance

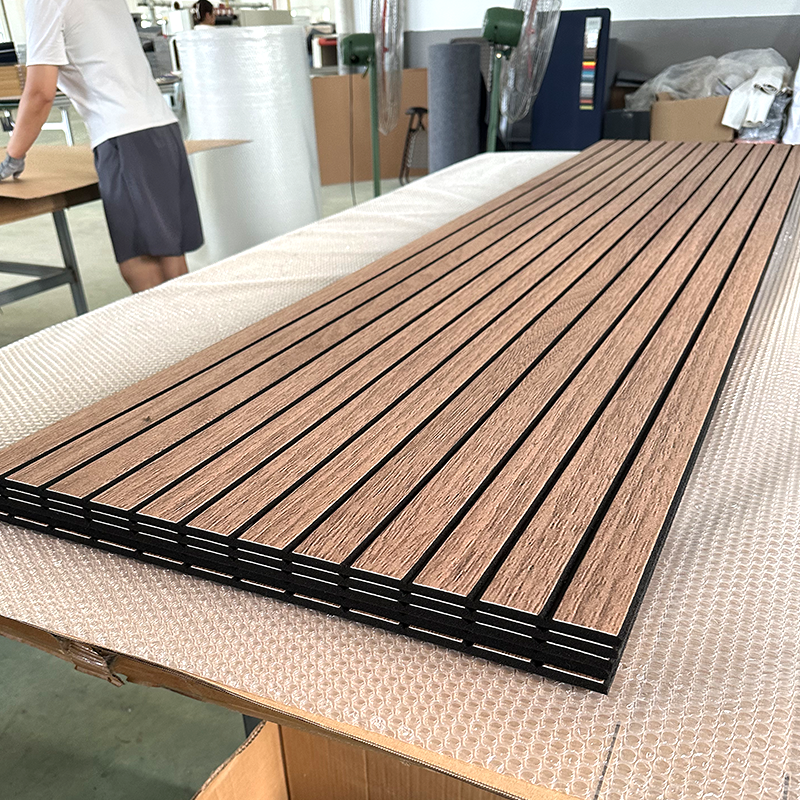

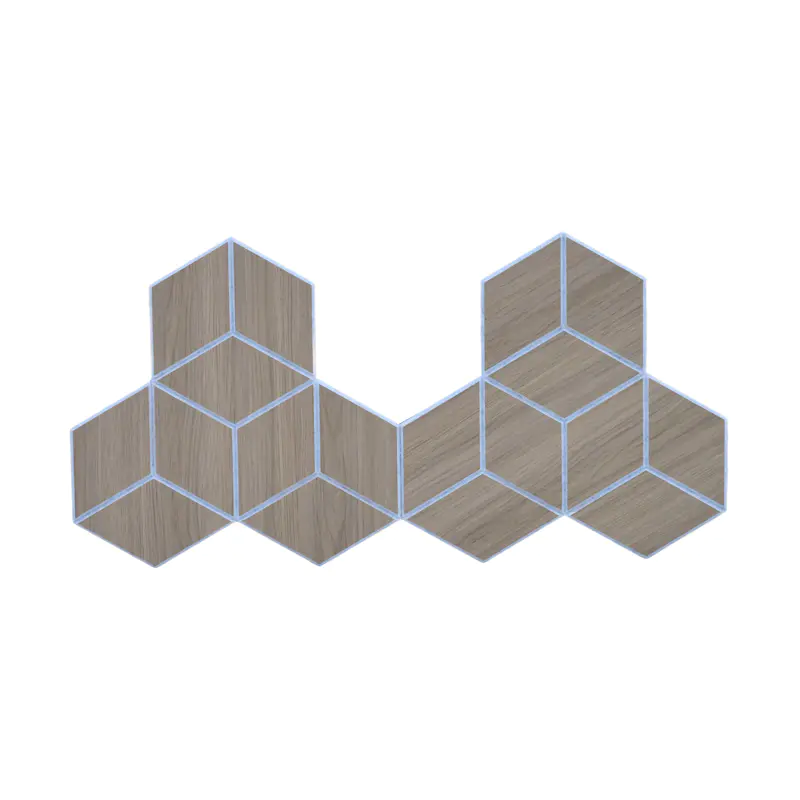

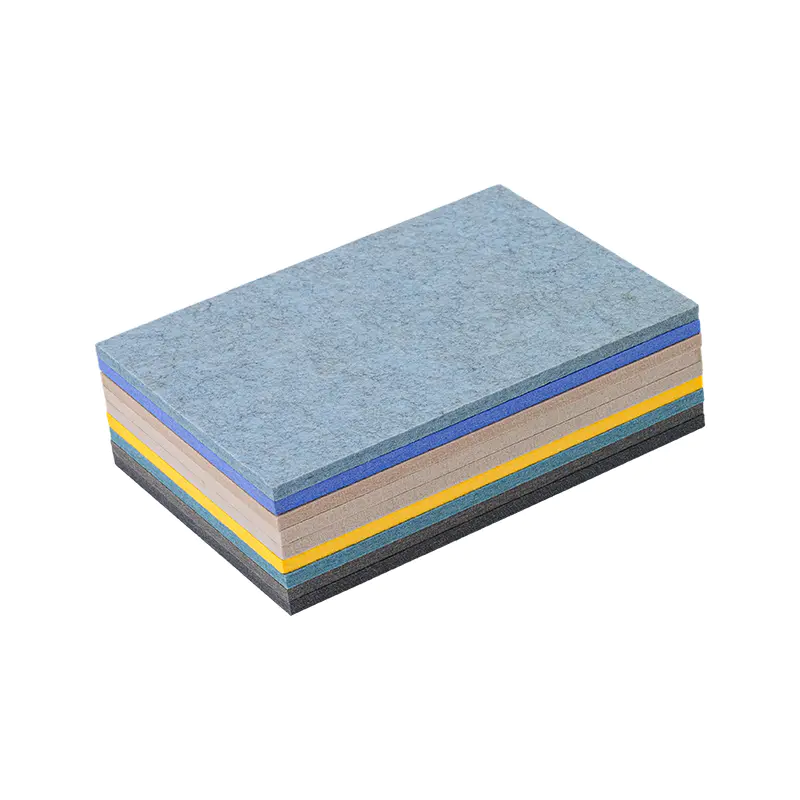

The procurement of Acoustic Wall Panels for commercial, corporate, or educational spaces involves a dual focus: optimizing noise reduction capabilities and ensuring a streamlined, cost-effective installation process. For large projects, installation speed and the reliability of the fixation method are as critical as the material's Noise Reduction Coefficient (NRC). High-performance polyester fiber panels, such as those manufactured by Yayin New Materials Jiangsu Co., Ltd., offer an NRC of 0.85, but this performance relies on proper mounting. Yayin New Materials, with a total operational area exceeding 30,000 square meters across facilities in Jiangsu, Zhejiang, and Jiangxi, specializes in carbon-neutral polyester fiber sound-absorbing materials. Our panels are manufactured using needle-punched non-woven technology, resulting in environmentally friendly materials that are sound-absorbing, flame-retardant, and decorative. Our products are certified to rigorous international standards, including NRC $\ge 0.85$, US standard ASTM E84 Class A, and formaldehyde emission E0.

II. Installation Protocol: Balancing Speed and Adhesion

The choice of installation method dictates project timeline, labor cost, and the panel's permanence. Installation ease for Acoustic Wall Panels is fundamentally determined by whether the project demands permanent adhesion or mechanical versatility.

A. Acoustic Wall Panel Installation Methods Comparison

Professional installation methods generally fall into two categories: direct adhesion and mechanical clipping. Direct adhesion offers the highest security and aesthetic simplicity, while mechanical fixing provides the most flexibility. A comparison of the two primary approaches reveals trade-offs in labor and permanence:

| Method | Permanence Level | Typical Labor Time Per Panel | Substrate Suitability |

|---|---|---|---|

| Direct Adhesion (Construction Adhesive) | Permanent / High | Moderate (Requires Curing Time) | Drywall, Concrete, Wood |

| Mechanical Fixing (Z-Clips/Impaling Clips) | Semi-Permanent / Removable | Low (Drill and Attach) | Drywall, Metal Studs |

Direct adhesion using polymer-based construction adhesive is often faster for large, continuous surface coverage, though the necessary curing time must be factored into the project schedule.

B. Securing Acoustic Wall Panels to Drywall

Drywall is the most common substrate, and securing acoustic wall panels to drywall requires careful selection of the bonding agent or mechanical anchors. For adhesives, high-tack, high-solids construction adhesives are preferred for their superior shear strength and minimal cure time. Conversely, if a mechanical fix is used, the clips must be secured using specialized drywall anchors (e.g., toggle bolts or self-drilling anchors) to ensure the hardware's pull-out strength exceeds the panel's weight and any potential external forces.

III. Common Fixation Techniques and Hardware Selection

Mechanical fixation methods are frequently favored by B2B clients who require the ability to adjust or replace panels without damaging the underlying wall surface.

A. Acoustic Panels Mounting Hardware Selection

For a professional finish, the proper acoustic panels mounting hardware selection is paramount. Z-clips and impaling clips are industry staples. Z-clips provide a secure, concealed mounting system where a bottom track is fixed to the wall and a corresponding clip is fitted to the panel's back, allowing the panel to hang precisely. Impaling clips, typically paired with adhesive, provide immediate structural support while the adhesive cures. Critically, these mechanical systems often facilitate the creation of an intentional air gap (usually 25mm-50mm) between the panel and the wall, which significantly boosts low-frequency absorption and improves the overall NRC rating.

B. Removable Acoustic Wall Panels Mounting System

For tenants or facilities with rotating design schemes, the removable acoustic wall panels mounting system is essential. Specialized systems utilize dual-locking fasteners (similar to French cleats) or magnetic strips. These allow the entire panel to be lifted and detached rapidly for access to utilities, wall cleaning, or relocation. This flexibility offers a strong value proposition for clients focused on asset management and workspace adaptability.

IV. Solutions for High-Efficiency Projects

In environments such as corporate offices, schools, and healthcare facilities, minimizing disruption and maximizing installation throughput is critical.

A. Quick-Install Polyester Acoustic Panels for Offices

The inherent lightness and robustness of Yayin's carbon-neutral polyester fiber panels make them ideal for quick-install polyester acoustic panels for offices. They can be easily cut on-site using standard utility knives, reducing installation errors and waste. For the fastest possible deployment, a factory-applied Pressure Sensitive Adhesive (PSA) backing is the most efficient choice, eliminating the need for wet adhesives, clamping, or curing time, provided the wall surface is clean, dry, and non-porous. A comparison of two fast-track methods:

| Method | Installation Preparation Requirement | Cure Time Required | Removal / Repositioning Ease |

|---|---|---|---|

| PSA Peel-and-Stick Backing | Minimal (Clean, Flat Surface) | None (Instant Adhesion) | Difficult (May Damage Substrate) |

| Lightweight Z-Clips | Moderate (Locate Studs/Use Anchors) | None | Easy (Designed for Removal) |

V. Compliance and Material Assurance

For B2B buyers, the ease of installation must not compromise regulatory compliance. Yayin ensures its sound-absorbing, flame-retardant, and heat-insulating panels meet the highest standards. With fire ratings including US ASTM E84 Class A and EU EN13501-1 Class B, and an E0 level for formaldehyde emission, our Acoustic Wall Panels guarantee safety alongside acoustic performance. Our material quality, backed by ISO9001 and ISO14001 certifications, provides confidence that the product installed quickly will also perform reliably and safely for the project's lifespan.

VI. Simplicity Meets Specification

Efficient installation is a cornerstone of modern acoustic treatment projects. Whether utilizing direct adhesion for permanent security or employing specialized acoustic panels mounting hardware selection for adaptability, the ease and speed of mounting Acoustic Wall Panels are paramount to project success. By selecting lightweight, dimensionally stable materials and the appropriate fixation system—from quick-install polyester acoustic panels for offices to highly versatile removable acoustic wall panels mounting system—project managers can ensure both rapid deployment and certified acoustic performance.

VII. Frequently Asked Questions (FAQs)

Q1: Which installation method provides the best sound absorption for Acoustic Wall Panels?

- A: The most effective method acoustically is typically mechanical fixing (like Z-clips) that creates a controlled air gap (25mm to 50mm) between the panel and the wall. This gap increases the system's efficiency, particularly for absorbing lower frequency sound waves.

Q2: What is the main benefit of the removable acoustic wall panels mounting system for commercial clients?

- A: The main benefit is operational flexibility. Removable systems (e.g., French cleats or magnetic mounts) allow facilities to easily access electrical wiring, perform maintenance, clean the wall surface, or relocate the panels entirely without material damage, which is ideal for leased or high-change environments.

Q3: When securing acoustic wall panels to drywall using adhesives, what is the best practice?

- A: Use a high-tack, polymer-based construction adhesive (not silicone or liquid nails) applied in a dense pattern of vertical beads or small mounds. Always ensure the drywall surface is clean and dust-free to guarantee maximum long-term adhesion.

Q4: Are quick-install polyester acoustic panels for offices compliant with fire safety standards?

- A: Yes, high-quality polyester fiber panels, such as those from Yayin, are engineered to meet strict fire standards. Our panels achieve Class A ratings under US ASTM E84 and UL723-2018, ensuring they are suitable for use in commercial offices and public spaces.

Q5: Why is acoustic panels mounting hardware selection important for precision?

- A: Hardware like Z-clips ensures precise, level installation and alignment across multiple panels. This is crucial for both aesthetic appearance and for maintaining the engineered air gap, ensuring consistent acoustic performance across the entire treated surface.