+86-180 3665 1199

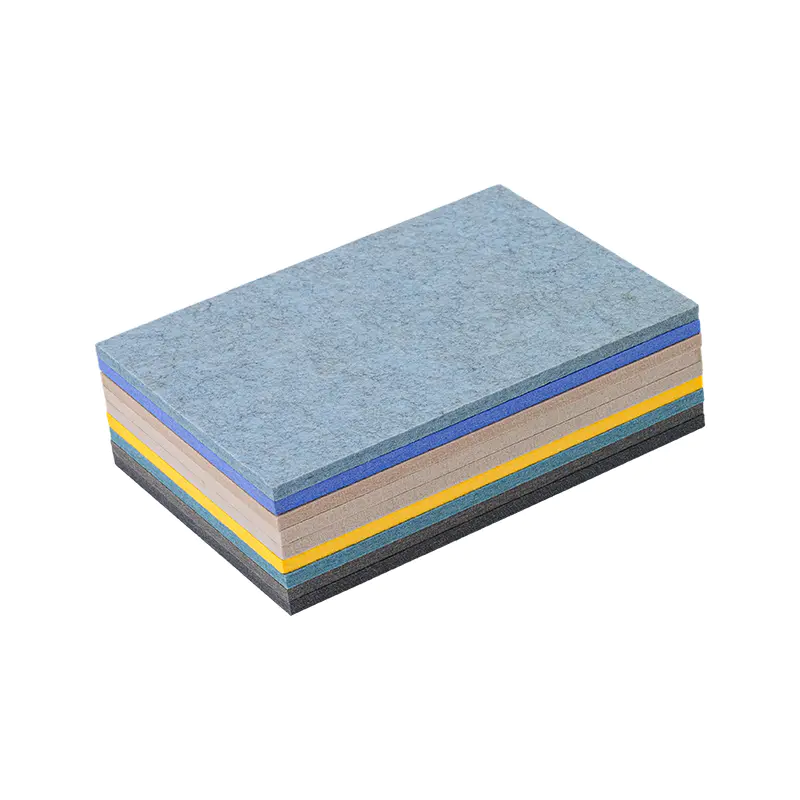

In the high-density environment of a modern call center, acoustic management is not just a luxury; it is a critical component of operational efficiency. Excessive ambient noise leads to operator fatigue, reduced speech clarity, and decreased customer satisfaction. Acoustic Desk Screens engineered from 95% recycled PET (Polyethylene Terephthalate) fibers have emerged as the premier solution for these challenges. Yayin New Materials Jiangsu Co., Ltd., a leader in carbon-neutral polyester fiber materials, utilizes advanced needle-punched non-woven technology to transform recyclable PET into high NRC acoustic panels for office desks. With production facilities spanning 30,000 square meters, we provide solutions that achieve a Noise Reduction Coefficient (NRC) of 0.85, significantly outperforming traditional office partitions.

The Physics of Noise Reduction: NRC and Speech Intelligibility

The effectiveness of an Acoustic Desk Screens setup is measured primarily through its Noise Reduction Coefficient (NRC). While a standard glass or wooden divider merely reflects sound waves, creating echoes, a 95% PET panel absorbs sound energy by converting kinetic air vibrations into low-grade heat within its fibrous matrix. According to the 2024 International Well Building Institute (IWBI) Sound Concept guidelines, optimizing background noise levels in open-plan offices can improve task performance by up to 15%. For a call center, using a 95% PET sound absorbing desk divider ensures that the "speech range" frequencies (typically 500Hz to 2000Hz) are captured, thereby preventing "cross-talk" between adjacent workstations.

Source: International WELL Building Institute - 2024 Sound Concept Standards

Comparative Analysis: PET vs. Conventional Materials

While traditional acrylic or laminate screens provide a visual barrier, they offer negligible acoustic absorption, whereas Acoustic Desk Screens provide a dual-function solution for privacy and decibel reduction.

| Material Type | Absorption (NRC) | Acoustic Function |

| Standard Acrylic/Glass | 0.05 - 0.10 | Reflective (Increases Echo) |

| Fabric-Wrapped Particle Board | 0.25 - 0.40 | Minimal Absorption |

| 95% PET sound absorbing desk divider | 0.85 | High Absorption (Dissipates Energy) |

Flame Retardancy and International Compliance for B2B Procurement

For large-scale call center fit-outs, safety compliance is as vital as acoustic performance. PET materials produced by Yayin are not only effective in sound management but also meet rigorous global fire safety standards. Our panels reach the A level of the US standard ASTM E84 and the B level of the EU standard EN13501-1. This is critical because fire rated acoustic desk screens for call centers must ensure that in the event of an emergency, the partitions do not contribute to smoke toxicity or rapid flame spread. According to the 2025 Global Office Furniture Safety Assessment by the Business and Institutional Furniture Manufacturers Association (BIFMA), the integration of flame-retardant polyester fibers has become a mandatory specification for sustainable enterprise-level workspace design.

Source: BIFMA - 2025 Office Furniture Safety and Sustainability Standards

Comparison: Fire Safety Ratings by Region

Ensuring that your custom size PET acoustic screens for workstations meet local codes is essential for passing building inspections and reducing insurance liabilities.

| Standard Body | Requirement | Yayin PET Performance |

| US ASTM E84 | Class A (Flame Spread 0-25) | Compliant (Level A) |

| EU EN13501-1 | Class B (Limited Contribution to Fire) | Compliant (Level B) |

| EU UL723-2018 | Surface Burning Characteristics | Compliant (Level A) |

Sustainability and the Carbon-Neutral Workplace

Modern enterprises are increasingly focused on their Environmental, Social, and Governance (ESG) goals. Choosing eco friendly polyester desk screens for open offices helps organizations achieve carbon neutrality. Yayin's needle-punched technology avoids the use of harmful chemical binders, ensuring that formaldehyde emissions reach the E0 level. This technical detail ensures that the air quality in the call center remains healthy for employees during long shifts. Furthermore, for those seeking wholesale 95% PET acoustic desk screens, the recyclability of the material ensures that the products support a circular economy model, significantly reducing the environmental footprint of the office facility.

- Needle-Punched Non-Woven Tech: Increases the surface area of fibers for maximum sound entrapment.

- E0 Formaldehyde Rating: Guaranteed safe for indoor air quality and long-term exposure.

- Antibacterial Properties: Critical for shared call center environments to maintain hygiene.

- Thermal Insulation: PET panels provide secondary energy savings by stabilizing desk-level temperatures.

Frequently Asked Questions (FAQ)

1. How much actual decibel reduction can I expect?

While Acoustic Desk Screens cannot block 100% of sound (since sound travels over the top), they typically reduce localized ambient noise by 5 to 10 decibels, which can perceive as a 50% reduction in "noise annoyance" in a call center setting.

2. Is 95% PET durable enough for high-traffic offices?

Yes. Our high NRC acoustic panels for office desks are manufactured using needle-punched technology, making them highly resistant to impact, fraying, and tacking (using pins for notes).

3. Can these screens be customized for specific desk sizes?

Absolutely. We provide custom size PET acoustic screens for workstations to fit any furniture configuration, ensuring seamless integration with existing office layouts.

4. Are PET screens difficult to clean?

No, the fibers are inherently resistant to moisture and can be easily cleaned with standard upholstery cleaners or a vacuum, making them ideal fire rated acoustic desk screens for call centers where cleanliness is paramount.

5. Why choose Yayin over other acoustic brands?

Yayin offers a direct-from-factory wholesale 95% PET acoustic desk screens solution with certified NRC 0.85 performance and A-level fire ratings, combining technical excellence with carbon-neutral production.