In contemporary interior design and architectural acoustics, the demand for functional yet aesthetically pleasing sound-absorbing solutions has surged. Among the diverse options available, printed image fabric wrapped acoustic panels have emerged as a versatile choice, offering not only effective sound control but also customizable visual appeal. These panels integrate the principles of acoustic engineering with artistic expression, making them suitable for a wide range of environments, including corporate offices, educational facilities, hospitality venues, and public spaces.

Understanding Printed Image Fabric Wrapped Acoustic Panels

At their core, printed image fabric wrapped acoustic panels consist of a high-performance acoustic substrate, typically composed of polyester fiber or other sound-absorbing materials, covered with a printed fabric layer. This fabric can feature custom images, patterns, or designs, allowing architects and designers to achieve both auditory comfort and visual impact. Unlike traditional plain acoustic panels, the printed designs enhance the spatial aesthetics without compromising sound performance.

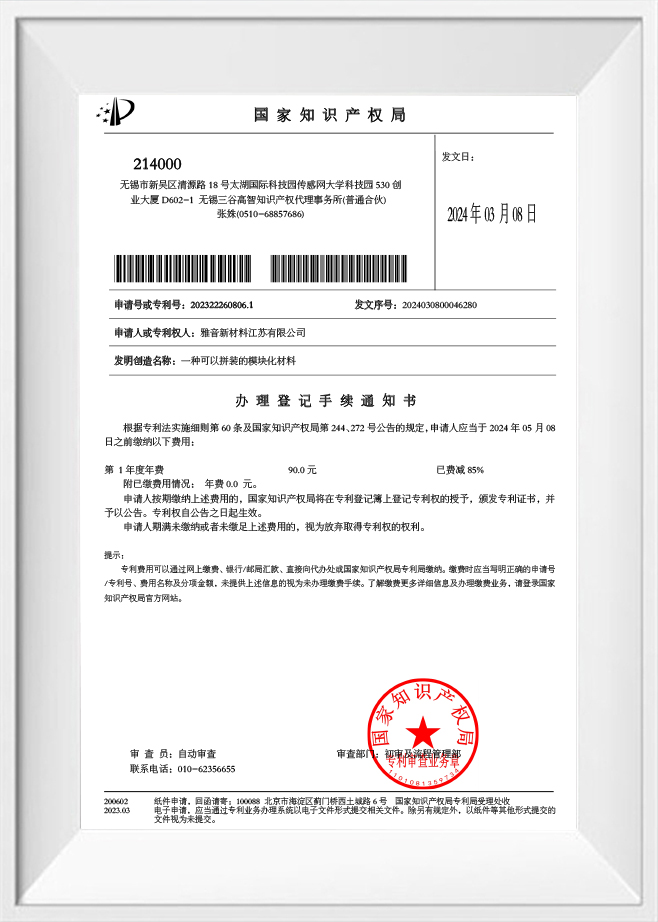

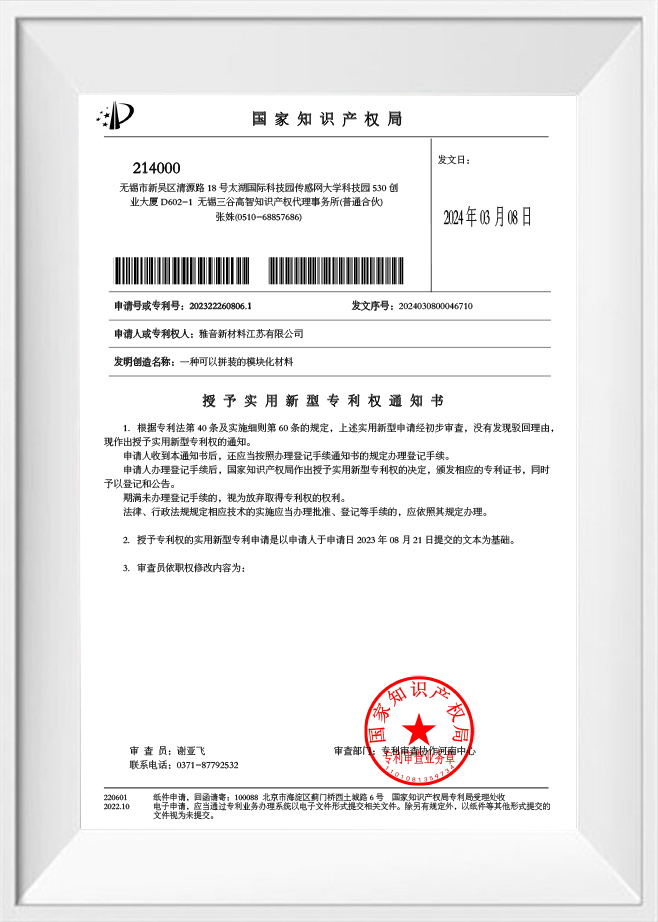

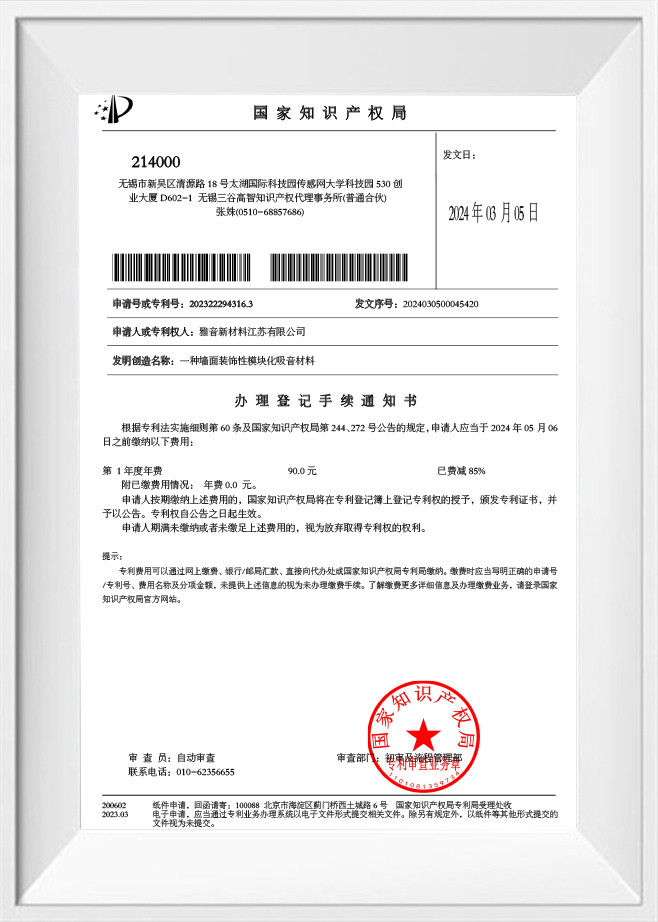

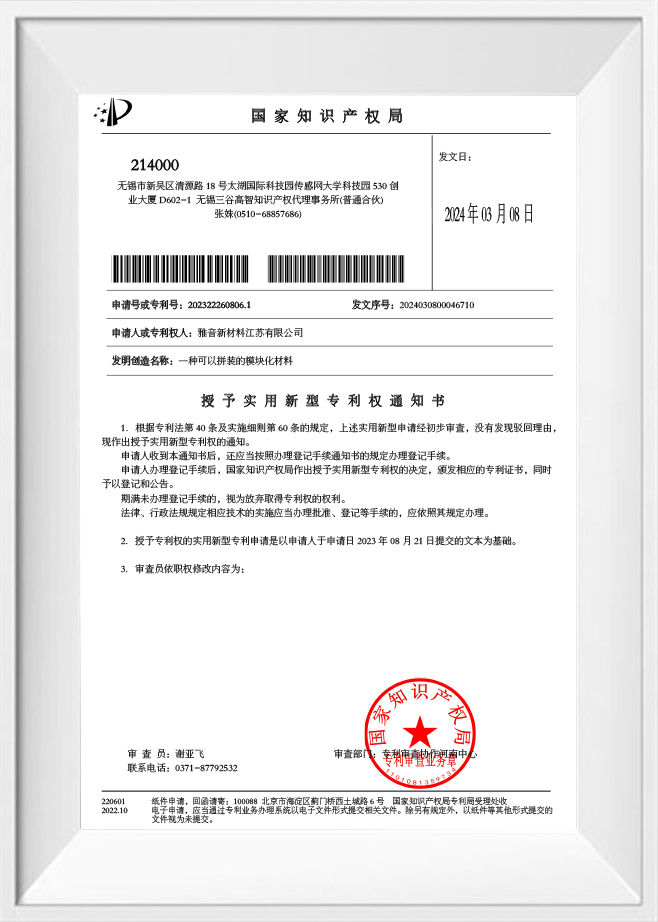

The core material often plays a pivotal role in sound absorption. Yayin New Materials Jiangsu Co., Ltd. specialize in carbon-neutral polyester fiber antibacterial sound-absorbing materials. By employing needle-punched non-woven technology, recyclable polyester is transformed into eco-friendly panels that are not only sound-absorbing but also flame-retardant, heat-insulating, and decorative. This dual functionality addresses both the acoustic requirements and sustainability considerations increasingly demanded in modern construction projects.

Key Characteristics and Advantages

Acoustic Performance

The primary function of these panels is to reduce noise and improve sound quality within a space. The core substrate absorbs sound waves, minimizing echo and reverberation. The efficiency of absorption depends on factors such as panel thickness, density, and the design of the surface. Printed image fabric wrapped acoustic panels maintain high-performance acoustic properties while adding a customizable decorative layer.

Customizable Visual Design

One of the distinguishing features of printed image panels is their visual versatility. Designers can integrate company logos, thematic imagery, abstract patterns, or artistic photography directly onto the fabric surface. This capability transforms functional acoustic solutions into integral elements of interior design, enhancing brand identity, ambiance, and user experience.

Environmental Sustainability

Sustainability is a critical concern in modern material selection. The panels produced by Yayin New Materials leverage recyclable polyester fibers, which reduce environmental impact while maintaining high durability and sound-absorbing efficiency. These panels are also carbon-neutral, aligning with global initiatives to lower carbon footprints in construction and interior design.

Fire and Heat Safety

In commercial and public spaces, fire safety is non-negotiable. Advanced printed image fabric wrapped acoustic panels incorporate flame-retardant treatments, ensuring compliance with building codes while maintaining material integrity under heat exposure. The heat-insulating properties further contribute to energy efficiency in indoor environments.

Antibacterial and Hygienic Properties

The antibacterial nature of the polyester fiber used in these panels provides additional value, particularly in environments such as healthcare facilities, schools, and offices where hygiene is critical. These materials inhibit microbial growth on the panel surfaces, reducing potential health risks.

Production and Quality Assurance

Producing high-quality printed image fabric wrapped acoustic panels requires precision in both material selection and manufacturing processes. Yayin New Materials Jiangsu Co., Ltd. emphasizes stringent quality control procedures, with experienced QC teams following rigorous protocols to ensure high-grade production. Key aspects of quality management include:

- Material Consistency: Ensuring the polyester fibers maintain uniform density and thickness for consistent acoustic performance.

- Printing Precision: Advanced printing technology guarantees color fidelity, sharpness, and durability of the images on the fabric surface.

- Panel Assembly: Panels are wrapped and finished to meet aesthetic and acoustic standards, with careful attention to edge finishing and structural integrity.

Service and Logistics

Beyond manufacturing, service quality is crucial for project success. Yayin provides 24-hour professional support to address customer inquiries, project requirements, and after-sales issues. Efficient service ensures that architects, designers, and contractors can rely on timely communication and technical guidance.

Logistics and delivery also play a pivotal role in large-scale installations. Yayin maintains a stable and rapid transport system, ensuring that all products reach project sites quickly and intact. This capability is particularly important for time-sensitive commercial projects where installation schedules are strict.

Applications Across Industries

Printed image fabric wrapped acoustic panels are highly adaptable and have been employed in diverse settings:

- Corporate Offices: Enhancing employee comfort by reducing background noise while reinforcing brand aesthetics through custom imagery.

- Educational Institutions: Classrooms, lecture halls, and libraries benefit from improved acoustics and visual engagement.

- Hospitality and Entertainment: Restaurants, hotels, theaters, and conference centers use printed panels to create unique thematic experiences without sacrificing sound quality.

- Healthcare Facilities: Antibacterial properties and acoustic control contribute to safer and more comfortable patient environments.

The combination of acoustic efficiency, visual customization, and sustainable production makes these panels a compelling choice for designers seeking multi-functional solutions.

Innovation and Future Trends

As the demand for sustainable and visually engaging interior materials grows, the printed image fabric wrapped acoustic panels market is likely to expand further. Technological advancements in digital printing, acoustic modeling, and eco-friendly materials will allow even greater precision in customizing panels to meet both aesthetic and functional requirements.

Yayin New Materials Jiangsu Co., Ltd. continuously innovates, integrating advanced polyester fiber technology to enhance the recyclability, antimicrobial properties, and acoustic efficiency of its panels. This investment in research and development ensures that the panels not only meet current design trends but also future requirements for environmental responsibility and indoor acoustics.

Conclusion

The evolution of printed image fabric wrapped acoustic panels reflects a broader shift in architectural design toward multi-functional, aesthetically flexible, and environmentally responsible materials. By combining superior sound absorption, customizable visual appeal, and sustainable production practices, these panels represent a sophisticated solution for modern acoustic challenges.