How do I determine the right thickness of sound absorbing materials for my space?

Introduction

Choosing the correct sound absorbing materials is a critical factor in creating environments with optimal acoustics. Whether you are designing a cinema, office, school, hospital, or residential interior, the thickness of the panels or materials used directly influences sound absorption performance. Sound absorbing materials work by reducing sound reflections, controlling reverberation, and improving speech intelligibility. Selecting the right thickness ensures that the space achieves the intended noise reduction while maintaining aesthetic and safety standards.

Understanding sound absorption and material performance

What makes sound absorbing materials effective?

Sound absorbing materials operate by converting sound energy into heat through friction within the material's fibers or porous structure. This process reduces reflected sound, making the environment quieter and more acoustically controlled.

Key properties that influence effectiveness include:

- Noise reduction coefficient (NRC): This rating measures the material's ability to absorb sound. Materials with higher NRC values, such as 0.85, absorb a significant portion of sound across a wide frequency range.

- Density and porosity: Denser materials with appropriate pore structures capture more sound energy, especially at lower frequencies.

- Thickness: Thicker panels generally provide better low-frequency absorption, while thinner panels are effective at mid-to-high frequencies.

The NRC and thickness together define how a material performs in a given space. When determining the thickness, it is essential to balance acoustic needs, structural limitations, and aesthetic considerations.

How thickness affects absorption

The thickness of sound absorbing materials influences the frequency range they effectively absorb. Thicker panels improve low-frequency absorption, which is important in large spaces such as cinemas or auditoriums, where bass sounds are prominent. Conversely, thinner panels may suffice in small offices or meeting rooms where mid-to-high frequency control is more critical.

A table below illustrates the general relationship between thickness and frequency absorption:

| Panel Thickness |

Effective Frequency Range |

Typical Applications |

| 10–20 mm |

1000–4000 Hz |

Offices, classrooms, residential interiors |

| 25–50 mm |

500–2000 Hz |

Conference rooms, exhibition halls, hospitals |

| 50–100 mm |

100–1000 Hz |

Cinemas, theaters, music studios, large halls |

This table provides a guideline; actual requirements depend on room size, ceiling height, and the desired acoustic performance.

Factors to consider when selecting thickness

Room size and volume

Larger spaces typically require thicker sound absorbing materials to manage low-frequency reverberation. In contrast, smaller rooms can achieve effective sound control with thinner panels. Ceiling height also affects the choice: higher ceilings necessitate thicker panels to maintain acoustic balance.

Intended use of the space

Different applications have specific acoustic requirements:

- Offices and meeting rooms: Clear speech intelligibility is crucial, often achieved with mid-frequency absorption using panels 20–40 mm thick.

- Cinemas and theaters: Low-frequency control is critical; panels 50–100 mm thick may be necessary.

- Hospitals and classrooms: A balance of speech clarity and general noise reduction is needed, typically addressed by medium-thickness panels (30–50 mm).

Material properties

The choice of material also affects the required thickness. Carbon-neutral polyester fiber antibacterial sound-absorbing materials provide high performance with moderate thickness due to their dense, needle-punched nonwoven structure. Materials with higher NRC ratings may require less thickness to achieve the same acoustic effect as lower-performance alternatives.

Installation and aesthetic considerations

Installation location can influence thickness decisions. Wall-mounted panels may have space constraints, while ceiling or free-standing panels allow for thicker materials. Sound absorbing materials should complement the interior design without compromising aesthetics. Customizable shapes, colors, and patterns help integrate panels seamlessly into the space.

Industry standards and certifications

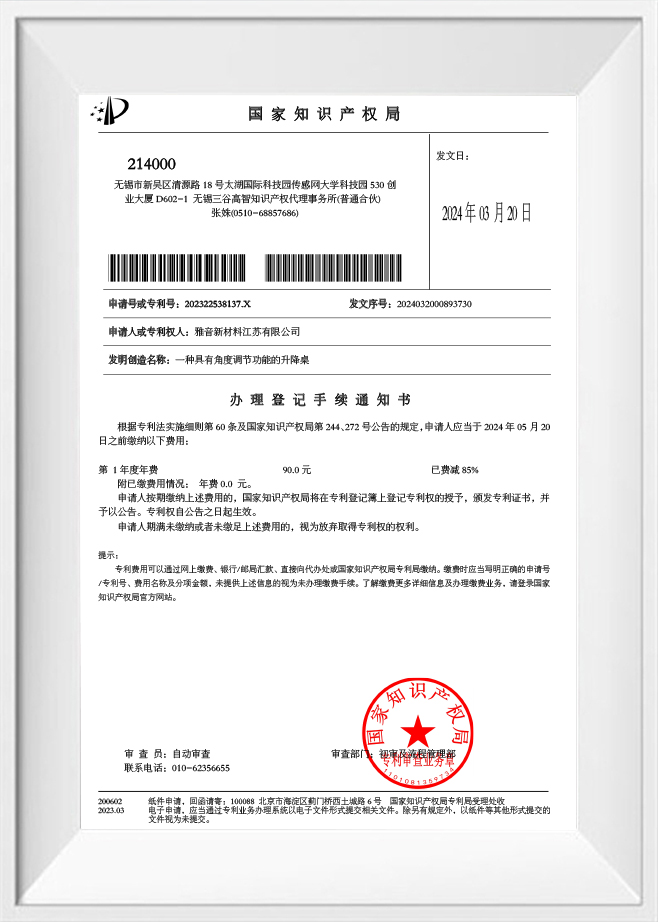

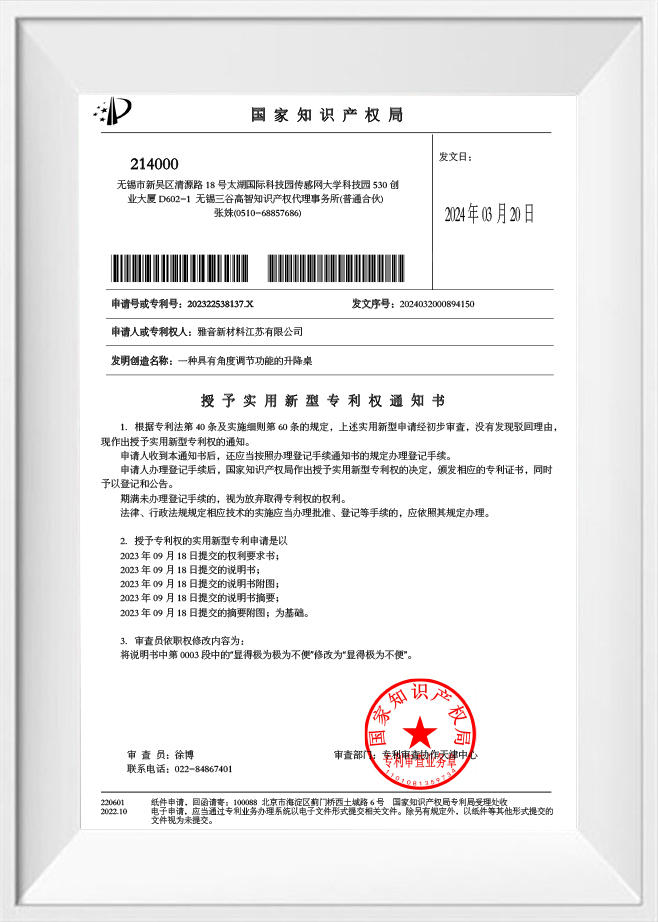

Professional installations rely on standards to ensure safety and performance. When selecting sound absorbing materials, consider certifications such as:

- Fire resistance: Materials should meet ASTM E84, EN13501-1, or UL723-2018 standards. Panels from reputable manufacturers often achieve A or B levels, ensuring compliance with building codes.

- Environmental safety: Low formaldehyde emissions (E0 level) and recycled content are increasingly important for eco-friendly building practices.

- Quality management: ISO9001 and ISO14001 certifications ensure consistent product quality and environmental responsibility.

These certifications indicate that a material is not only effective but also safe and environmentally responsible.

Recommendations for determining the right thickness

- Identify the primary noise frequencies: Determine whether low, mid, or high frequencies dominate the space.

- Measure room dimensions: Calculate the volume and surface areas that require coverage.

- Select material with appropriate NRC: High NRC materials reduce the need for excessive thickness.

- Balance aesthetics and functionality: Consider panel thickness in relation to ceiling height, wall depth, and design preferences.

- Consider professional guidance: Acoustic consultants or manufacturers can provide recommendations based on project specifications.

Yayin New Materials Jiangsu Co., Ltd. provides a range of panels processed with needle-punched nonwoven technology, allowing customization in thickness, color, and shape to meet specific acoustic requirements.

Practical examples of thickness selection

Office spaces

In open-plan offices or conference rooms, mid-frequency absorption is prioritized. Panels around 25–40 mm thick can reduce reverberation while maintaining visual harmony. Sound absorbing materials with flame-retardant properties and antibacterial surfaces further enhance the safety and comfort of the environment.

Cinemas and theaters

Low-frequency absorption is critical in entertainment spaces. Panels of 50–100 mm thickness, strategically positioned on walls and ceilings, ensure uniform acoustic performance. High NRC ratings, such as 0.85, maximize sound absorption efficiency.

Educational and healthcare facilities

Classrooms and hospitals require a balance between speech clarity and noise reduction. Panels 30–50 mm thick are typically installed to reduce echo, improve communication, and enhance patient or student comfort. Customizable sound absorbing materials allow integration with interior décor without compromising performance.

Conclusion

Determining the right thickness of sound absorbing materials involves a careful assessment of the room's acoustic needs, the material's properties, and the intended use of the space. Thicker panels generally improve low-frequency absorption, while thinner panels are adequate for mid-to-high frequencies. Incorporating NRC ratings, fire safety, and environmental certifications ensures optimal performance and compliance with standards.

By consulting with professional manufacturers and considering project-specific requirements, you can select sound absorbing materials that provide effective noise control, durability, and aesthetic compatibility. Companies like Yayin New Materials Jiangsu Co., Ltd. offer customizable, eco-friendly solutions that meet both technical and design requirements for modern spaces.