How does Soundproofing Acoustic Felt compare to other soundproofing materials?

Soundproofing acoustic felt has become an increasingly popular choice in modern architecture and interior design for noise reduction and acoustic treatment. Its ability to combine sound absorption, flame retardancy, and environmental sustainability makes it distinct from other traditional materials.

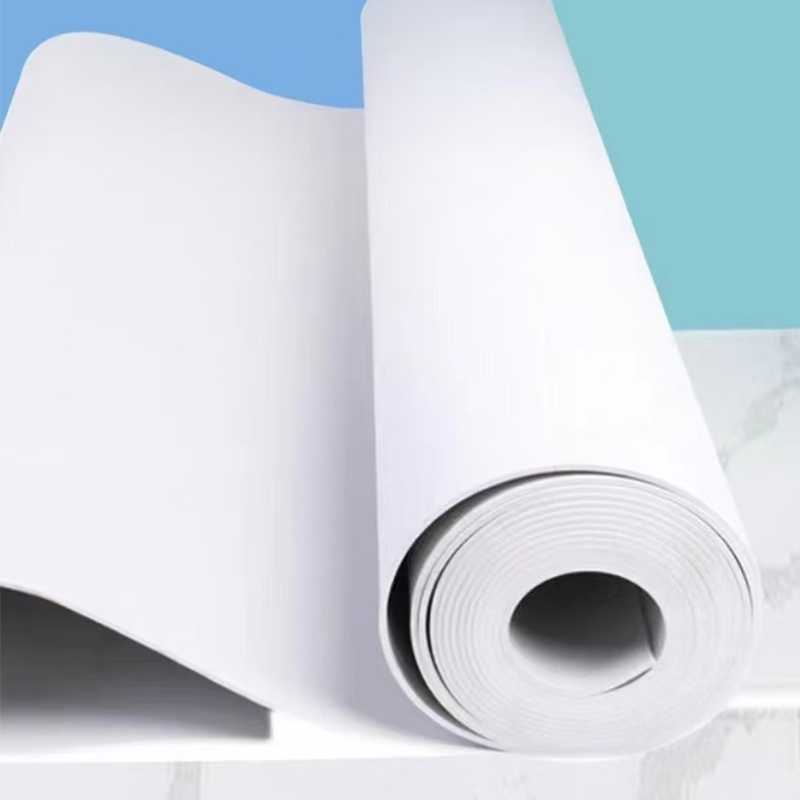

What is Soundproofing Acoustic Felt?

Soundproofing acoustic felt is a high-performance material designed to reduce unwanted noise and improve room acoustics. It is generally made from needle-punched nonwoven polyester fibers, which can be processed into panels, rolls, or custom shapes. Its primary function is absorbing sound waves, minimizing echo, and enhancing acoustic comfort.

Unlike ordinary insulation materials, soundproofing acoustic felt offers both sound absorption and thermal insulation. It is lightweight, flexible, and environmentally friendly, making it suitable for various spaces, including offices, schools, cinemas, hospitals, and residential interiors.

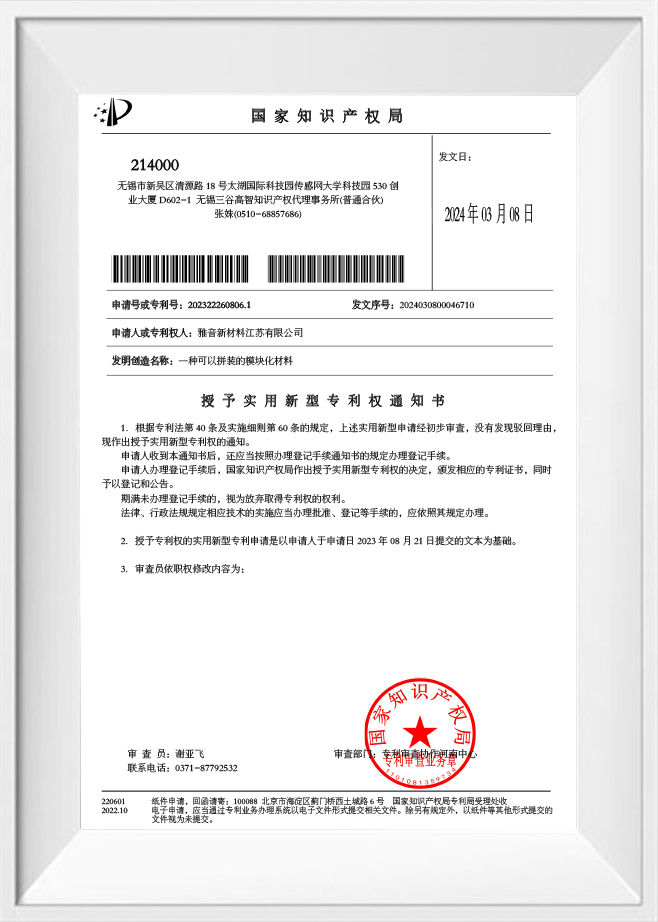

Yayin New Materials Jiangsu Co., Ltd. uses carbon-neutral polyester fibers to manufacture soundproofing acoustic felt, ensuring that their products are recyclable and meet strict safety standards. The panels achieve a noise reduction coefficient (NRC) of 0.85 and comply with international fire safety standards, including ASTM E84 and EN13501-1.

Comparison with Other Soundproofing Materials

Fiberglass Panels

Fiberglass panels are widely used for soundproofing due to their affordability and effectiveness. However, unlike soundproofing acoustic felt, fiberglass can be irritating to handle and may release harmful particles into the air. Its thermal insulation properties are good, but it lacks the decorative flexibility that felt panels provide.

Mineral Wool

Mineral wool is dense and offers excellent sound absorption and fire resistance. While it performs well in industrial applications, it is heavier and less adaptable for interior design purposes. Soundproofing acoustic felt, by contrast, can be easily cut into custom shapes and installed without specialized equipment.

Acoustic Foam

Acoustic foam is lightweight and commonly used for reducing mid-to-high frequency noise, but it is less effective in absorbing low-frequency sounds. Its decorative options are limited, and it does not provide significant thermal insulation or flame-retardant properties. Soundproofing acoustic felt offers a more comprehensive solution for environments that require both aesthetic appeal and high acoustic performance.

Mass Loaded Vinyl (MLV)

Mass loaded vinyl is highly effective for blocking sound transmission through walls and ceilings due to its density, but it is heavy and can be challenging to install. Unlike MLV, soundproofing acoustic felt is lighter, more environmentally friendly, and customizable, providing flexibility for diverse architectural projects.

Technical Advantages of Soundproofing Acoustic Felt

Noise Reduction

The needle-punched structure of acoustic felt allows it to trap and dissipate sound waves efficiently. Its NRC rating of 0.85 makes it highly effective in both commercial and residential spaces, surpassing many standard soundproofing materials in multi-frequency absorption.

Fire Safety

Soundproofing acoustic felt produced by Yayin meets A-level fire safety standards, including ASTM E84 and UL723-2018. This ensures that installations are safe in high-risk environments, such as schools, hospitals, and public venues.

Environmental Benefits

The use of recycled polyester fibers makes soundproofing acoustic felt an eco-friendly option. It can be processed using needle-punched nonwoven technology, which reduces waste and promotes sustainable building practices.

Design Flexibility

Soundproofing acoustic felt panels are available in a variety of colors, patterns, and shapes, allowing designers to integrate acoustic solutions seamlessly into interior decor. This adaptability is a key advantage over traditional rigid materials like mineral wool or MLV.

Thermal Insulation

In addition to noise control, soundproofing acoustic felt provides moderate thermal insulation, contributing to energy efficiency in indoor spaces. This dual functionality distinguishes it from single-purpose materials like acoustic foam.

Applications in Different Industries

Office and Meeting Rooms

In office environments, soundproofing acoustic felt helps reduce speech interference, enhancing productivity and privacy. Panels can be installed on walls, ceilings, or partitions to optimize acoustic performance without compromising aesthetics.

Cinemas and Entertainment Venues

For cinemas and theaters, high NRC-rated acoustic felt ensures clear sound quality by controlling echo and reverberation. Its fire-retardant properties also make it a safe choice for spaces with large audiences.

Healthcare Facilities

Hospitals and clinics benefit from acoustic felt because it helps maintain quiet and calm environments, essential for patient care and concentration. Its recyclable materials align with green building standards in medical facilities.

Educational Institutions

Classrooms and auditoriums require effective noise control to improve learning outcomes. Soundproofing acoustic felt absorbs background noise, ensuring that speech is intelligible and distractions are minimized.

Residential Interiors

Homeowners use acoustic felt in living rooms, home theaters, or bedrooms to enhance comfort by reducing external noise and internal echo. Its decorative potential allows it to blend with interior design seamlessly.

Key Considerations for Buyers

Material Quality

High-quality soundproofing acoustic felt is made from needle-punched polyester fibers, ensuring durability, fire safety, and consistent acoustic performance. Buyers should verify ISO9001 and ISO14001 certifications to ensure compliance with quality and environmental standards.

Thickness and Density

The effectiveness of soundproofing acoustic felt depends on its thickness and density. Thicker panels generally provide better low-frequency absorption, while moderate density ensures balanced acoustic performance across multiple frequencies.

Installation Requirements

Soundproofing acoustic felt is easy to install with standard adhesives or mounting systems. Its lightweight and flexible structure allow for straightforward handling, unlike rigid materials such as mineral wool or MLV.

Customization

Projects often require unique sizes, shapes, or patterns. Leading manufacturers like Yayin offer customized acoustic solutions to match specific design and acoustic needs.

Table: Comparison of Soundproofing Materials

| Material |

NRC Rating |

Fire Resistance |

Environmental Impact |

Design Flexibility |

Ease of Installation |

| Soundproofing Acoustic Felt |

0.85 |

A-level |

High (recycled polyester) |

High |

Easy |

| Fiberglass Panels |

0.7 |

B-level |

Medium |

Medium |

Moderate |

| Mineral Wool |

0.8 |

A-level |

Medium |

Low |

Difficult |

| Acoustic Foam |

0.5 |

C-level |

Low |

Low |

Easy |

| Mass Loaded Vinyl |

0.6 |

B-level |

Low |

Low |

Difficult |

Conclusion

Soundproofing acoustic felt offers a balanced combination of noise reduction, fire safety, environmental sustainability, and design flexibility. Compared to traditional materials like fiberglass, mineral wool, acoustic foam, or mass loaded vinyl, it provides superior versatility for a wide range of applications. Its lightweight and customizable nature makes it ideal for offices, cinemas, schools, hospitals, and residential interiors.

By selecting high-quality soundproofing acoustic felt from reputable manufacturers, buyers can achieve effective acoustic control while adhering to environmental and safety standards. This positions acoustic felt as a modern and practical solution for both professional and personal spaces.