Understanding the Sound Absorption Efficiency of Polyester Fiber Acoustic Panels

Introduction

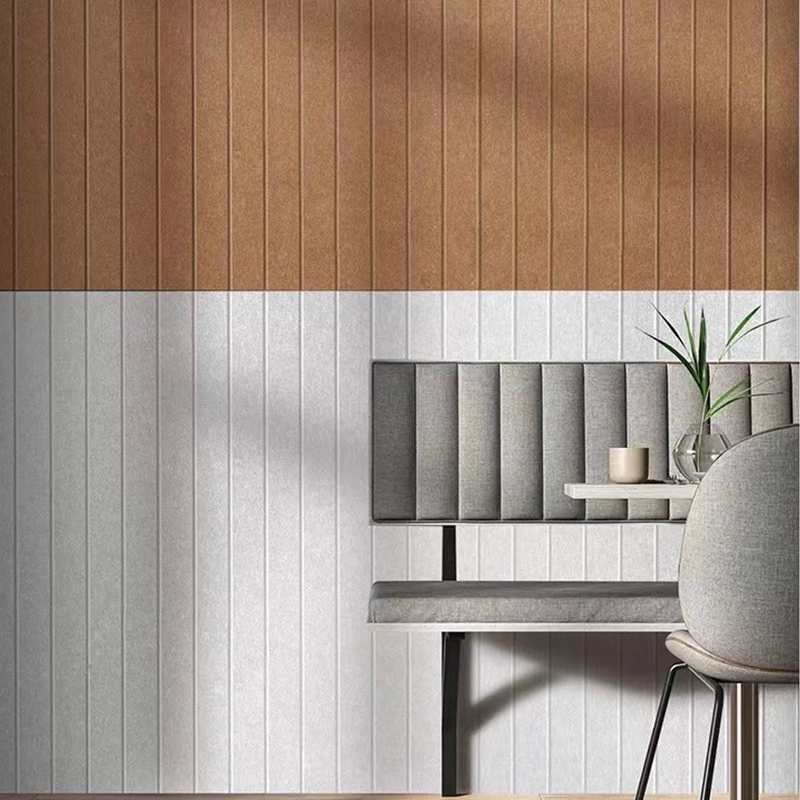

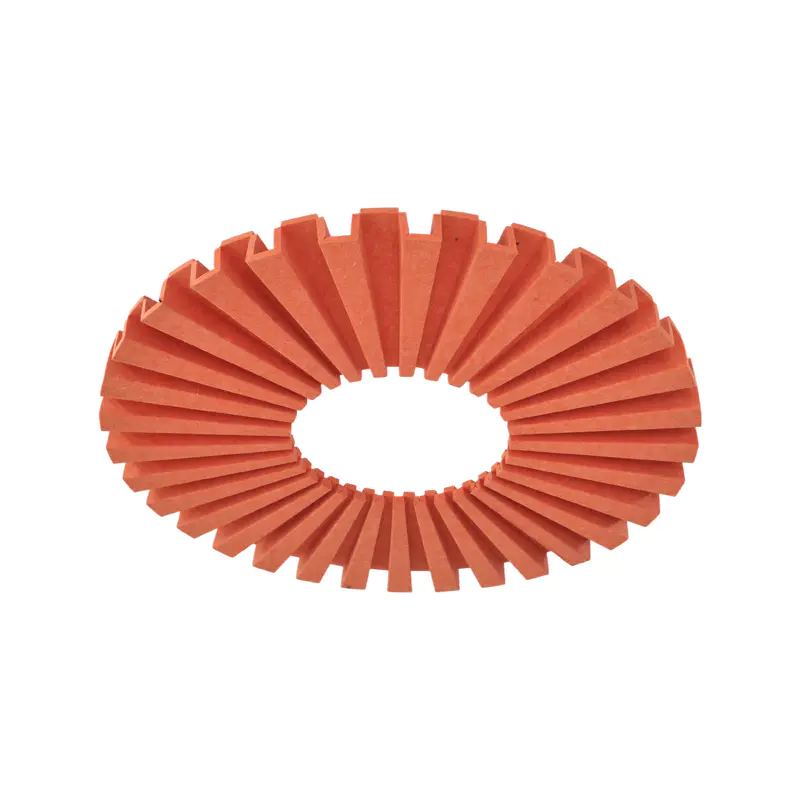

Polyester Fiber Acoustic Panels are widely used in modern architectural and interior design projects due to their excellent sound absorption performance, environmental friendliness, and aesthetic versatility. These panels help reduce reverberation, improve acoustic comfort, and create a quieter and more productive environment in offices, classrooms, theaters, and public spaces.

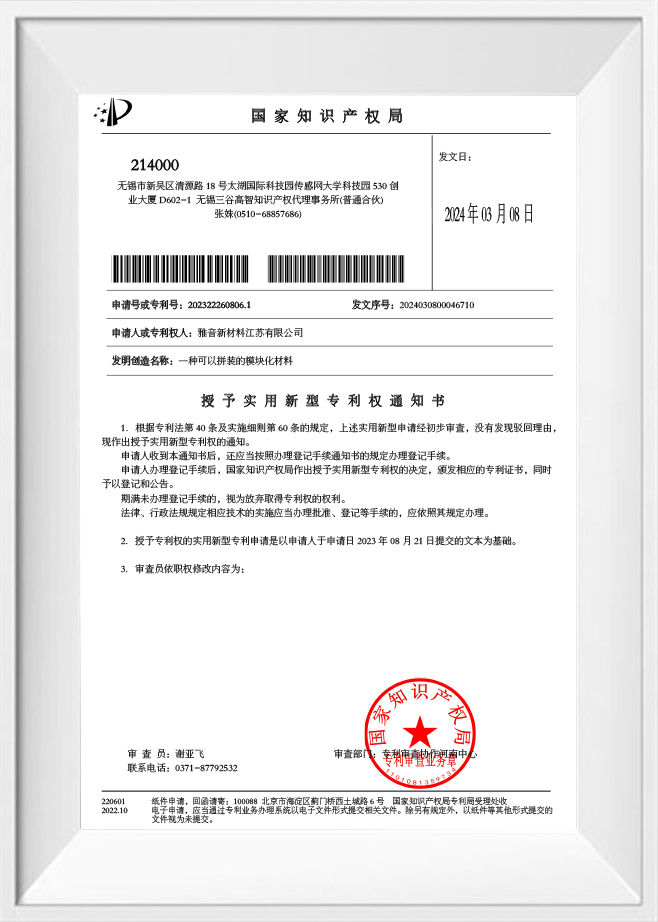

Yayin New Materials Jiangsu Co., Ltd. is a leading manufacturer in this field. Headquartered in Lianyungang, Jiangsu Province, the company operates two branch factories in Huzhou City, Zhejiang Province and Nanchang City, Jiangxi Province, covering a total area of more than 30,000 square meters. Yayin specializes in the research, development, production, and sales of carbon-neutral polyester fiber antibacterial sound-absorbing materials, employing needle-punched non-woven technology to transform recyclable polyester into eco-friendly panels that are sound-absorbing, flame-retardant, heat-insulating, and decorative.

1. Key Performance Parameters of Polyester Fiber Acoustic Panels

The following are the main technical specifications and parameters of Yayin’s Polyester Fiber Acoustic Panels:

- Noise Reduction Coefficient (NRC): Up to 0.85 — demonstrating excellent sound absorption performance across a wide range of frequencies.

- Flame Retardancy:

- A level under U.S. ASTM E84 standard

- B level under EU EN13501-1 standard

- A level under EU UL723-2018 standard

- Formaldehyde Emission: Meets E0 level under national environmental standards, ensuring healthy indoor air quality.

- Certifications:

- ISO9001 – Quality Management System Certification

- ISO14001 – Environmental Management System Certification

2. Mechanism of Sound Absorption

The sound absorption efficiency of polyester fiber acoustic panels mainly depends on their internal structure and material density. Yayin’s panels use a needle-punched non-woven process, creating a dense three-dimensional fiber network that allows sound waves to enter and convert acoustic energy into heat through friction and vibration. This significantly reduces echo and noise levels in enclosed spaces.

The panels perform effectively in the medium and high frequency range (500–4000 Hz), making them ideal for improving speech intelligibility and overall acoustic clarity in indoor environments.

3. Environmental and Functional Advantages

- Eco-Friendly: Made from recyclable polyester fiber, fully compliant with carbon-neutral principles.

- Flame-Retardant: Advanced treatment ensures safety in both commercial and residential applications.

- Thermal Insulation: Helps maintain indoor temperature stability, reducing energy consumption.

- Antibacterial and Formaldehyde-Free: Contributes to a healthy, non-toxic environment.

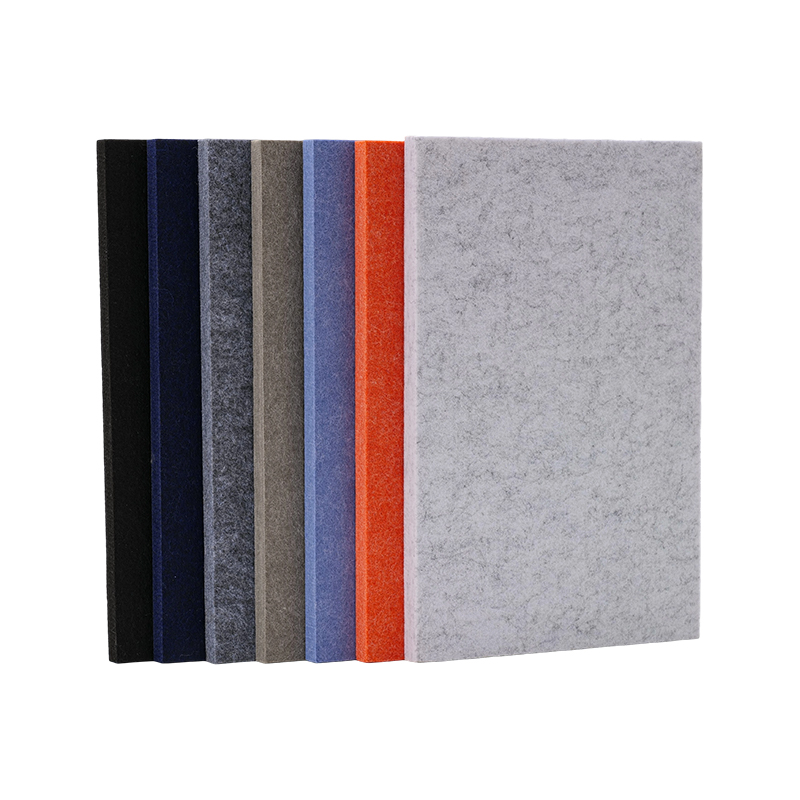

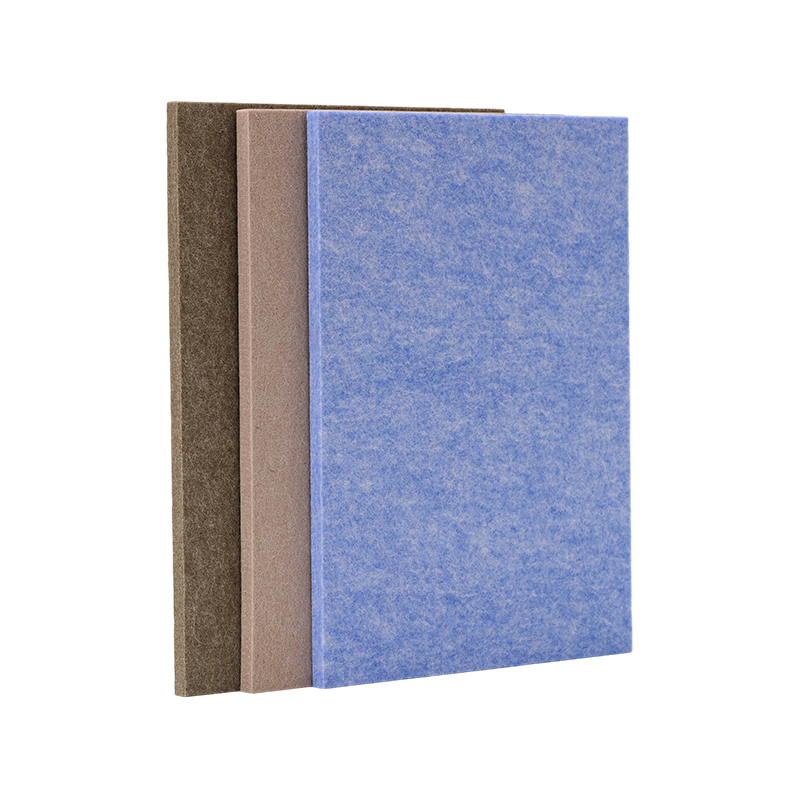

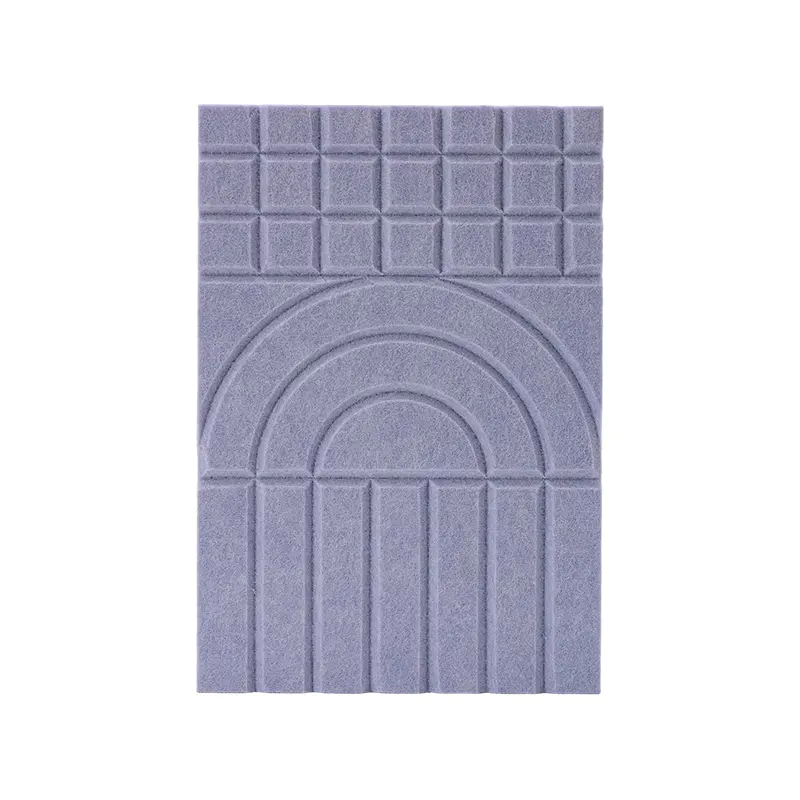

- Decorative Variety: Available in multiple colors and patterns for diverse interior design needs.

4. Application Scenarios

- Offices and conference rooms

- Educational institutions (classrooms, lecture halls)

- Theaters and music studios

- Public buildings and transportation hubs

- Residential soundproofing and home theaters

5. Conclusion

With an NRC value of 0.85 and compliance with multiple international flame retardant and environmental standards, the Polyester Fiber Acoustic Panels from Yayin New Materials Jiangsu Co., Ltd. represent a perfect balance of performance, sustainability, and aesthetics. Their advanced needle-punched non-woven technology ensures superior sound absorption, while the company’s commitment to quality and environmental responsibility makes Yayin a trusted partner in modern acoustic design.