How Fabric Wrapped Acoustic Panels Transform Acoustic Comfort in Commercial and Residential Spaces?

In contemporary architecture and interior design, managing sound quality has become a crucial aspect of creating functional and aesthetically pleasing environments. Fabric wrapped acoustic panels have emerged as a versatile solution for reducing noise, controlling reverberation, and enhancing the overall acoustic experience in both commercial and residential spaces. These panels combine the practical functionality of high-performance sound absorption with the aesthetic appeal of customizable fabric finishes, making them an increasingly popular choice among architects, designers, and acoustic engineers.

Overview of Fabric Wrapped Acoustic Panels

Fabric wrapped acoustic panels are engineered systems designed to absorb sound waves and minimize noise reflections within a given space. Unlike traditional acoustic solutions that may prioritize function over form, fabric wrapped panels offer the dual benefits of high acoustic performance and visual integration. Typically, these panels consist of a core sound-absorbing material, such as polyester fiber or mineral wool, which is then encased in a decorative fabric. This combination ensures that the panel performs efficiently while blending seamlessly with interior design schemes.

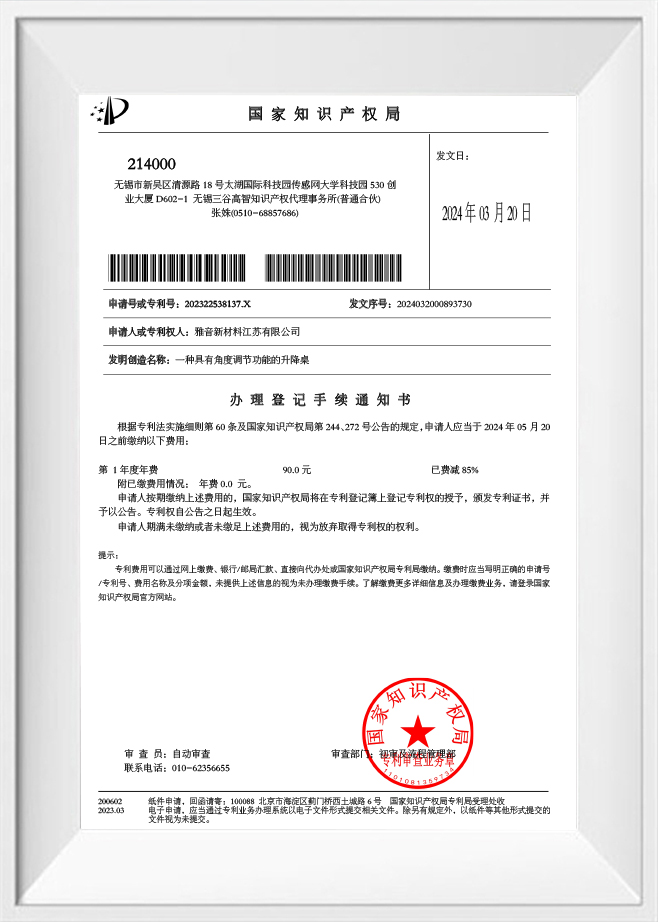

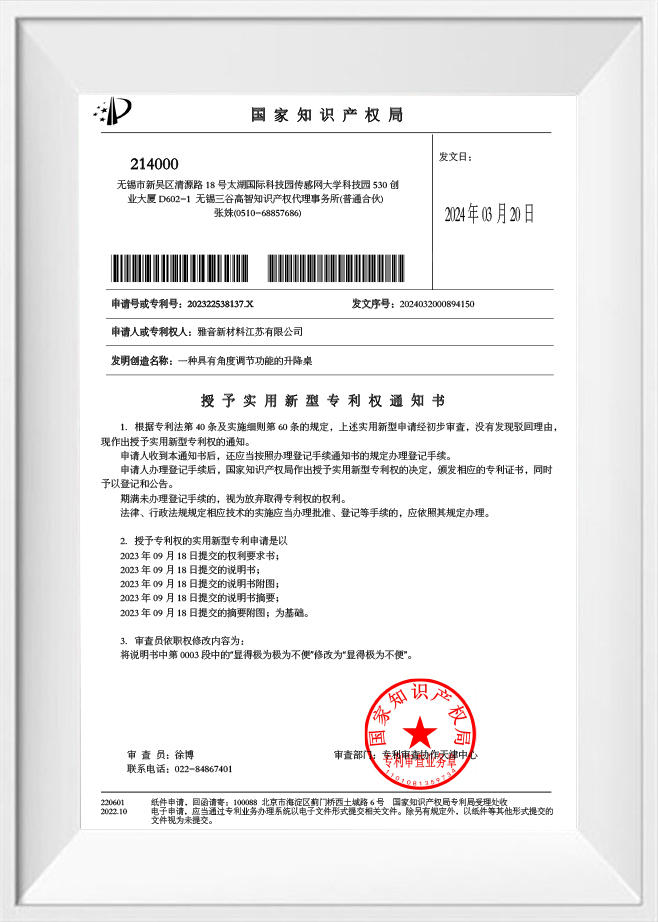

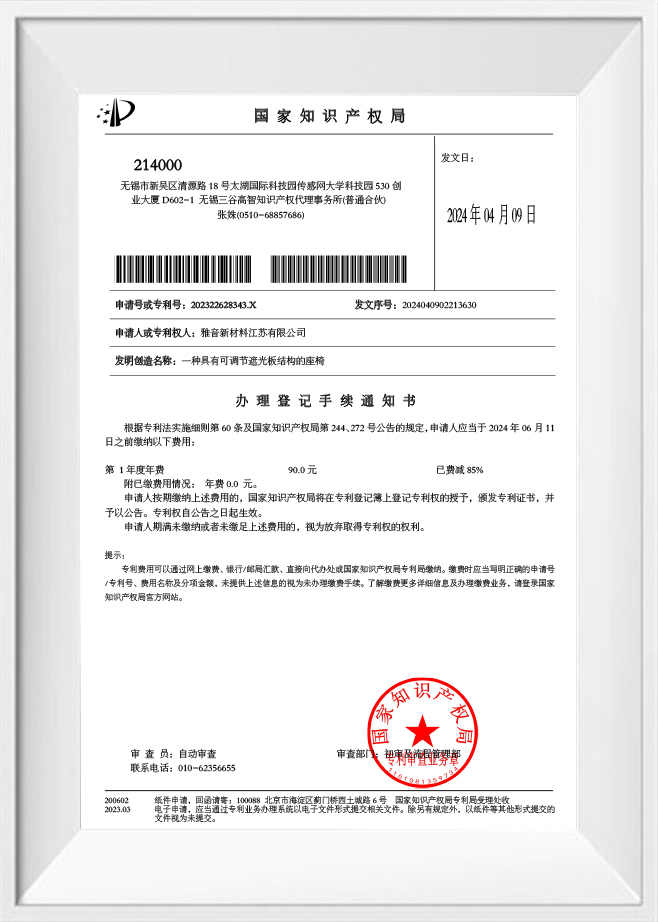

Yayin New Materials Jiangsu Co., Ltd. is a leading manufacturer and supplier specializing in custom sound absorbing panels. The company utilizes advanced needle-punched non-woven technology to transform recyclable polyester fibers into environmentally friendly acoustic panels. These panels are designed not only for superior sound absorption but also for flame retardancy, thermal insulation, and aesthetic versatility.

Material Composition and Acoustic Properties

The acoustic effectiveness of fabric wrapped panels is largely determined by the composition of the core material and the properties of the fabric covering. Polyester fiber cores are widely favored due to their lightweight, durable, and environmentally sustainable characteristics. When processed with needle-punched non-woven techniques, the fibers form a dense but breathable matrix capable of dissipating sound energy effectively.

Fabric coverings serve multiple purposes beyond aesthetics. They protect the core material from dust, wear, and damage while allowing sound waves to penetrate with minimal reflection loss. Fabrics may be natural, synthetic, or blends, selected for their acoustic transparency, durability, and fire resistance. Certifications such as ASTM E84 Level A, EN13501-1 at grade B, and UL723 Class A demonstrate the compliance of these panels with rigorous international safety and performance standards.

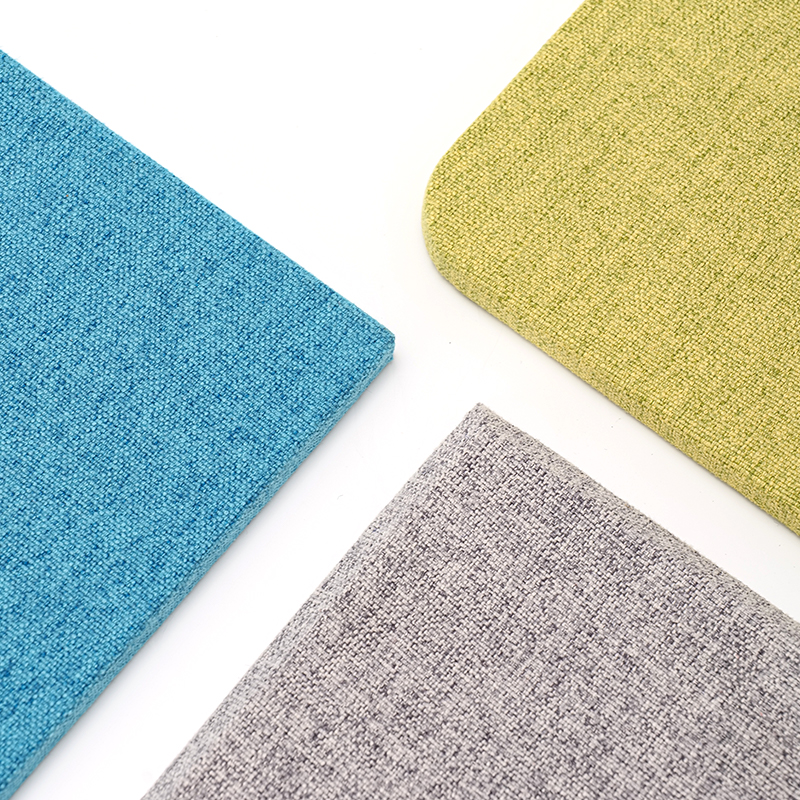

Design Flexibility and Customization

One of the most compelling advantages of fabric wrapped acoustic panels is their adaptability to diverse design requirements. Panels can be produced in various sizes, thicknesses, and edge profiles to accommodate both aesthetic and acoustic needs. Customizable fabric options allow designers to integrate panels with existing interior color schemes, textures, and patterns, thereby enhancing visual harmony without compromising functionality.

Yayin New Materials Jiangsu Co., Ltd.'s panels offer a variety of fabric textures and finishes while maintaining consistent performance standards. This combination of acoustic efficiency and decorative flexibility makes fabric-wrapped panels ideal for high-end commercial environments, theaters, conference rooms, educational institutions, and residential applications.

Environmental Considerations and Sustainability

Sustainability is a growing concern in material selection for modern construction. Yayin New Materials Jiangsu Co., Ltd. manufactures fabric-wrapped sound-absorbing panels focusing on carbon-neutral and recyclable materials. The polyester fibers used in these panels are derived from recyclable resources and processed using environmentally friendly technologies. These panels not only reduce the ecological footprint of buildings but also help companies obtain green building certifications.

The integration of environmentally friendly manufacturing processes with high-performance acoustic design reflects the increasing market demand for solutions that are both functional and responsible. This eco-conscious approach adds value to building projects by addressing both regulatory and consumer expectations regarding sustainability.

Performance Metrics and Standards Compliance

The performance of fabric wrapped acoustic panels is evaluated based on sound absorption coefficients, fire resistance, thermal insulation, and durability. International standards such as ASTM E84, EN13501-1, and UL723 provide benchmarks for fire safety, while acoustic testing methods quantify absorption performance across different frequencies. Compliance with PE0 level national certification further ensures that panels meet stringent domestic and international regulations.

Yayin's commitment to quality management, evidenced by ISO9001 and ISO14001 certifications, underscores its dedication to producing panels that consistently meet or exceed industry benchmarks. Such certifications also assure architects and contractors of product reliability, safety, and sustainability compliance.

Applications Across Different Environments

Fabric wrapped acoustic panels are widely applicable across diverse settings. In commercial spaces like offices, conference rooms, and auditoriums, these panels mitigate noise pollution, improve speech intelligibility, and enhance occupant comfort. In residential applications, they can be strategically installed in living rooms, home theaters, or open-plan areas to manage acoustic quality without compromising interior design aesthetics.

Yayin's panels are particularly suited for environments that require both acoustic performance and fire safety. Their flame-retardant properties, combined with heat-insulating capabilities, make them suitable for high-density and safety-conscious spaces. The panels' versatility in mounting—wall-mounted, ceiling-suspended, or free-standing—further extends their functional applicability.

Technical Advantages of Fabric Wrapped Acoustic Panels

Fabric wrapped acoustic panels provide several technical advantages over traditional soundproofing solutions. Their design allows for high sound absorption across a wide frequency range, effectively reducing reverberation in both low- and high-frequency ranges. This characteristic is particularly important in spaces like conference rooms, auditoriums, and studios, where clear speech intelligibility is crucial.

The use of polyester fiber cores, especially those processed with needle-punched non-woven technology, ensures uniform density and consistent acoustic performance. This method produces panels that are lightweight yet structurally robust, making them easy to handle, transport, and install. Furthermore, the needle-punched fiber structure allows for natural airflow through the panel, preventing moisture accumulation and reducing the risk of mold growth, thereby increasing the panel's longevity and maintaining indoor air quality.

Installation and Maintenance Considerations

Proper installation is essential to maximize the acoustic performance of fabric wrapped panels. Panels can be wall-mounted, ceiling-suspended, or integrated into partition systems depending on the specific acoustic requirements of the space. Modular panel designs allow for flexible layouts, enabling architects and acoustic engineers to strategically place panels for optimal sound absorption.

Maintenance is relatively straightforward. The fabric surface can be cleaned with gentle vacuuming or spot-cleaning to remove dust and debris. For panels exposed to high-traffic areas, removable fabric covers may be used, allowing for easy replacement or laundering without affecting the acoustic core. Yayin New Materials provides guidance and support to ensure correct installation, which further guarantees that panels maintain their sound absorption efficiency and aesthetic quality over time.

Future Trends in Acoustic Panel Technology

The market for fabric wrapped acoustic panels is evolving rapidly, driven by increasing awareness of acoustic quality and sustainable building practices. Emerging trends include:

- Eco-friendly Materials: Companies like Yayin focus on carbon-neutral and recyclable polyester fibers, aligning acoustic design with green building standards.

- Integration with Smart Building Systems: Panels are increasingly being designed to accommodate embedded technologies such as lighting, sensors, or digital display screens, providing multifunctionality.

- Customizable Acoustic Solutions: Demand for bespoke panel designs that meet both aesthetic and acoustic specifications continues to grow, leading manufacturers to offer greater variety in fabrics, colors, and textures.

- Enhanced Fire and Safety Standards: As safety regulations tighten, panels with higher flame-retardant properties and certifications are becoming standard, particularly for public and commercial spaces.

Conclusion: Why Fabric Wrapped Acoustic Panels are an Industry Essential

In summary, fabric wrapped acoustic panels represent a sophisticated balance between sound management, aesthetic design, and sustainability. Their high-performance polyester fiber cores, customizable fabric surfaces, and compliance with international safety standards make them ideal for a wide range of applications—from commercial offices and educational facilities to residential spaces and high-end entertainment venues.