In contemporary architectural design, the integration of effective acoustic solutions has become a fundamental requirement, not merely an aesthetic consideration. Among these solutions, fabric wrapped soundproofing acoustic panels have emerged as a preferred choice for a wide range of applications, from corporate offices and educational institutions to recording studios and hospitality environments. These panels serve dual purposes: controlling reverberation and mitigating unwanted noise, while maintaining a visually appealing environment. Their unique combination of functional performance and design flexibility has made them an essential component in both new construction and retrofit projects.

Composition and Material Innovation

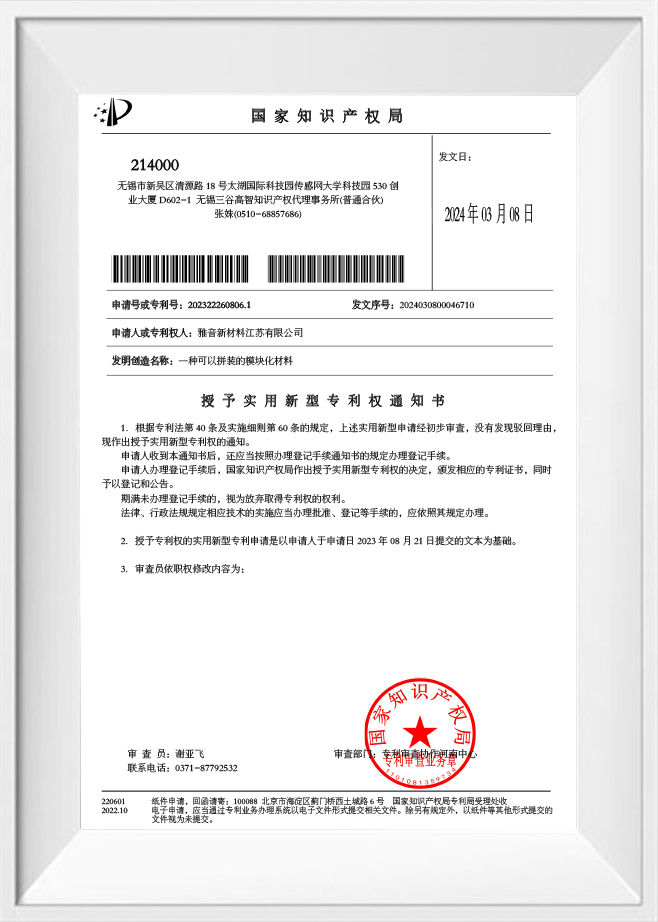

The core of fabric wrapped soundproofing acoustic panels lies in their material composition. Traditional panels often rely on mineral wool or fiberglass, but modern advancements have introduced high-performance polyester fiber and other sustainable materials. Yayin New Materials Jiangsu Co., Ltd. specializes in the research, development, production, and sales of carbon-neutral polyester fiber antibacterial sound-absorbing materials. Their panels utilize needle-punched non-woven technology, transforming recyclable polyester into environmentally friendly acoustic panels.

This innovative material provides several benefits. First, it enhances the noise reduction coefficient (NRC), achieving up to 0.85, indicating high sound absorption efficiency. Second, the panels are inherently flame-retardant, meeting rigorous standards such as ASTM E84 (A-level, US), EN13501-1 (B-level, EU), and UL723-2018 (A-level, EU). Additionally, the panels maintain E0-level formaldehyde emissions, aligning with stringent indoor air quality requirements. The combination of recyclability, sound absorption, and fire safety represents a significant step forward in sustainable acoustic solutions.

Acoustic Performance and Noise Control

Sound management is a critical aspect of modern spaces, and fabric wrapped acoustic panels excel in this domain due to their layered construction and density variations. The panels absorb mid-to-high frequency sound waves effectively, reducing echo and reverberation that can compromise speech intelligibility or audio quality. This makes them particularly suitable for open office layouts, conference rooms, theaters, and classrooms, where clarity of communication is essential.

The NRC value, a standardized measure of a material's sound absorption capacity, is a key metric in evaluating panel performance. Panels with an NRC of 0.85, like those produced by Yayin, are capable of absorbing a substantial portion of incident sound energy. This level of performance can significantly improve acoustic comfort in large spaces without requiring extensive structural modifications.

Design Flexibility and Aesthetic Integration

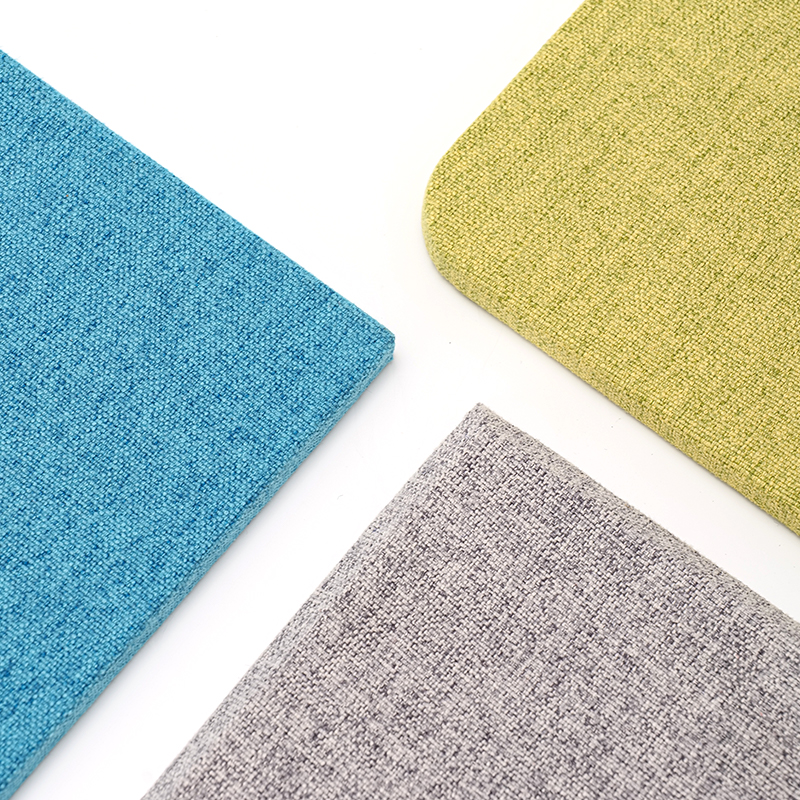

One of the standout advantages of fabric wrapped soundproofing acoustic panels is their visual versatility. Unlike exposed fiberglass panels, fabric-wrapped panels allow architects and interior designers to select from a wide range of colors, textures, and patterns. This aesthetic flexibility enables the panels to seamlessly integrate into the overall interior design concept while performing their acoustic function.

Yayin's panels offer customizable finishes that maintain the balance between functionality and style. These panels can be installed on walls, ceilings, or freestanding structures, providing designers with creative freedom to craft visually coherent and acoustically optimized environments.

Fire Safety and Regulatory Compliance

Fire resistance is a critical consideration in material selection, particularly in public and commercial buildings. The flame-retardant performance of fabric wrapped acoustic panels ensures compliance with national and international fire safety standards. Yayin panels, achieving ASTM E84 A-level and UL723-2018 A-level certifications, provide assurance that they will not contribute to fire propagation. Moreover, compliance with the EN13501-1 B-level standard in Europe further confirms their suitability for a wide array of construction codes.

Environmental Considerations and Sustainability

Sustainability has become a central concern in the construction and interior design industries. Modern fabric wrapped soundproofing acoustic panels emphasize environmentally responsible production processes. Yayin's panels, manufactured from recyclable polyester fibers, illustrate the potential for combining performance with environmental stewardship. By employing needle-punched non-woven technology, the company transforms polyester waste into high-performance panels, reducing landfill contributions and carbon footprint.

Furthermore, the panels meet strict formaldehyde emission requirements (E0 level), ensuring that indoor air quality is preserved. Companies seeking green building certifications, such as LEED or BREEAM, can benefit from integrating these panels into their designs, enhancing both environmental performance and occupant well-being.

Applications Across Diverse Environments

The versatility of fabric wrapped soundproofing acoustic panels extends across various industries:

- Corporate Offices: Reduce distractions in open-plan workspaces, enhancing employee focus and productivity.

- Educational Institutions: Improve speech intelligibility in classrooms and lecture halls.

- Recording Studios & Theaters: Optimize acoustic quality for high-fidelity sound reproduction.

- Hospitality & Healthcare: Maintain peaceful environments while integrating design elements that reflect brand identity.

By providing both acoustic functionality and aesthetic appeal, these panels fulfill critical needs across commercial, educational, healthcare, and entertainment sectors.

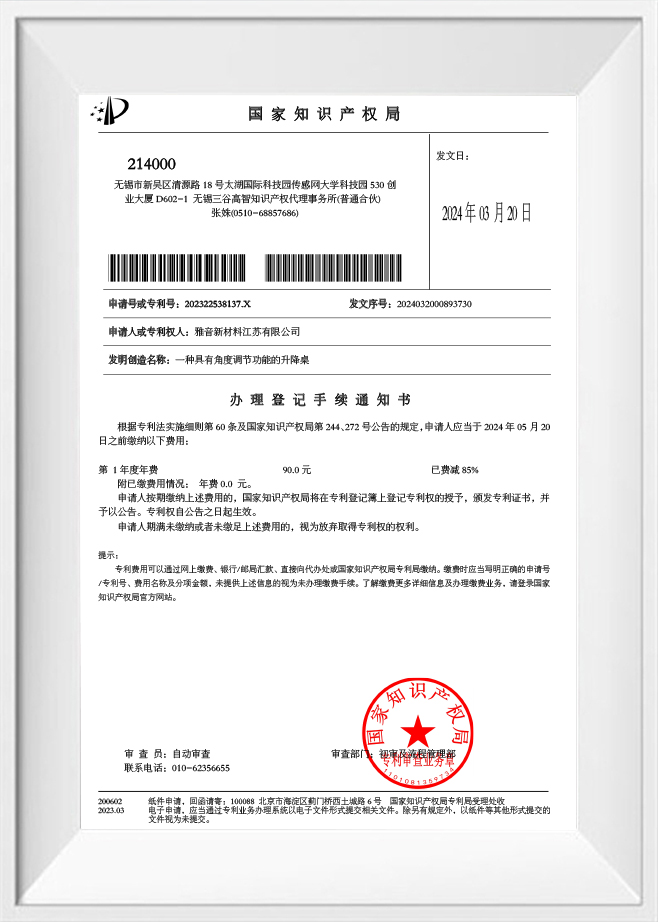

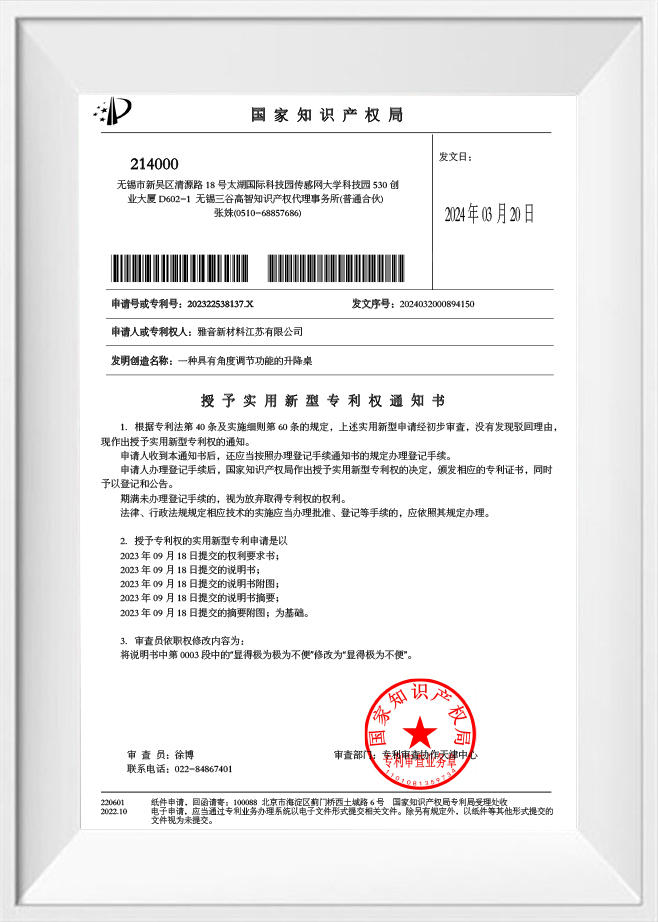

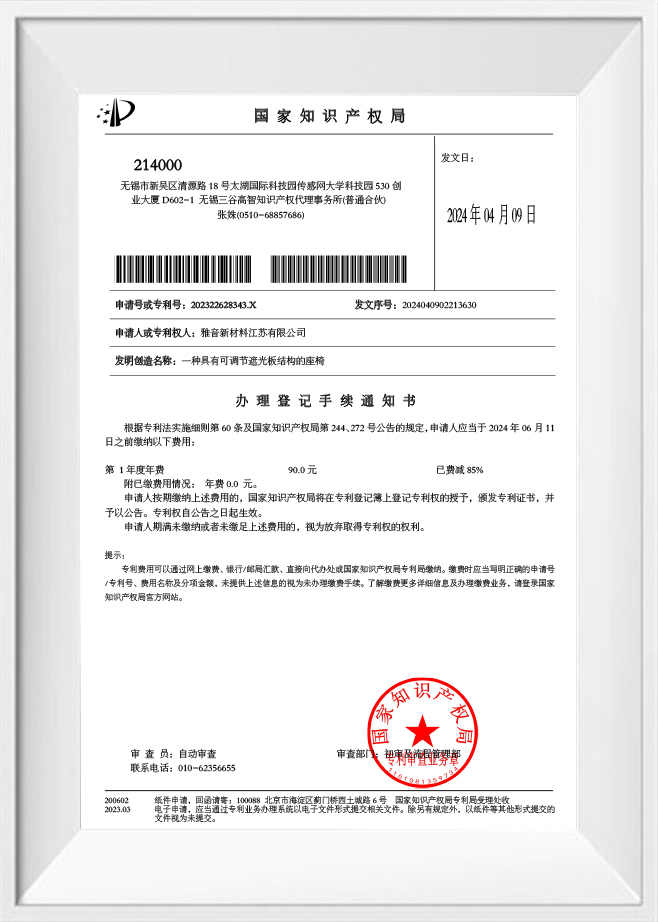

Manufacturing Standards and Quality Assurance

High-quality fabric wrapped soundproofing acoustic panels are backed by rigorous quality control measures. Yayin New Materials Jiangsu Co., Ltd. has obtained ISO9001 quality management system certification and ISO14001 environmental management system certification. These certifications ensure that each panel is manufactured according to uniform standards, thereby guaranteeing performance reliability and compliance with environmental regulations.

Through precise manufacturing processes, including careful fiber selection, controlled density, and uniform fabric wrapping, panels maintain consistent acoustic properties. Such standardization is crucial for projects requiring multiple panels to achieve uniform sound absorption across large areas.

Installation Considerations

Proper installation is vital for maximizing the performance of fabric wrapped soundproofing acoustic panels. Factors such as panel spacing, mounting techniques, and room geometry influence overall effectiveness. Adhesive mounts, mechanical fixings, and modular frame systems can be employed depending on the project requirements. Panels should also be installed with attention to fire safety regulations and accessibility for maintenance.

Future Trends in Acoustic Panel Technology

As buildings become more open and multifunctional, the demand for advanced acoustic solutions grows. Emerging trends in fabric wrapped acoustic panels include:

- Integration of antibacterial and antimicrobial treatments to enhance hygiene, particularly in healthcare and public spaces.

- Development of smart panels with embedded sensors for noise monitoring and adaptive sound management.

- Continued emphasis on sustainable materials, including post-consumer recycled fibers and bio-based composites.

Companies like Yayin are at the forefront of these innovations, leveraging research and development to create next-generation acoustic solutions that meet environmental, regulatory, and performance expectations.

Conclusion

Fabric wrapped soundproofing acoustic panels represent a convergence of material science, acoustic engineering, and interior design. They offer effective sound absorption, regulatory compliance, aesthetic versatility, and sustainable production methods.